![]()

The purpose of this document is to outline the basic steps to define the parameters and generate the BPA projections. The following sections are outlined in this document to assist the user in the required day-to-day tasks and represent the typical order of data entry and data generation.

The BRPA is a complex planning tool that provides a complete and efficient processing plan based on the parameters established by the customer. Several profiles can be created for targets, hatch calendars and placements which allow the users to generate multiple projections to analyze the various scenarios. Products can be assigned to groups which allow one product to be placed and another product to be processed. For example, a product can be placed as a broiler straight run and then be processed as either a large bird or small bird:

The following diagram represents the basic flow of all of the components in the BRPA process.

This section will guide the user to set up all prerequisites needed to operate BRPA.

The Setup section contains the following components:

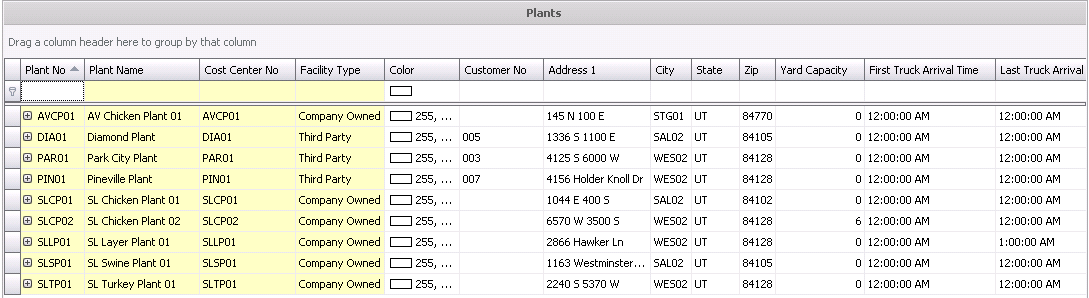

Processing plants can be created as internal or external facilities. Plants are defined based on one cost center per plant. The cost center must be created before the plant is created. Address information is entered as well as latitude and longitude details for mapping. The child grids for each plant contain details related to line speeds, weight and down time however the many of these fields are required for LHS only. The fields outlined below are related to BRPA.

In Admin>General>Definitions>Facilities, select Plants.

Select the  button,

and a new line will appear.

button,

and a new line will appear.

Enter the Plant No.

Enter the Plant Name.

Select the Cost Center No.

Select the Facility Type. Options will be Company Owned or Third Party. Third Party must be assigned to a cost center that has the Cost Center Type=External.

Select the Customer No if the plant is a third party plant that will be receiving birds from farms. This will be the Ship-to customer defined in Customers>Business Usages in Customers.

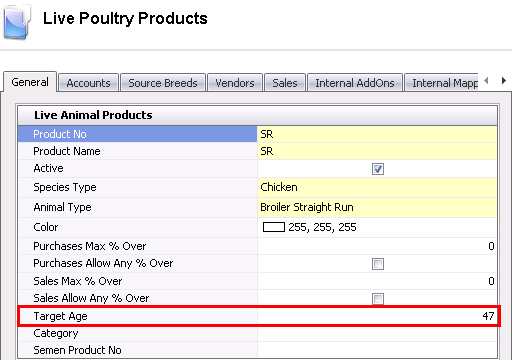

The products must be established based on how the birds are processed. Products will have been set up prior to BRPA during BRIM or HIM implementation. For BRPA configuration, the Target Age needs to be entered based on the number of days from placement to processing. As well, there is an option in BRPA to use Product Groups. Product groups are used to group products under one target or to be able to enter different weights for one product. The group product is used in BRPA targets. If the same product will be processed at different weights, then a product needs to be created for each weight group and mapped to the original product. The product group must be created in the same manner as Products then mapped using the Internal Mapping tab. This will be used later in the BRPA Master Data>Product Groups to configure further details.

The following topics are covered in this section:

In General>General>Products>Animals, select Poultry.

In the Target Age field, enter the number of days from placement to processing. This is required for BRPA to project schedules for the product.

Close and save the product.

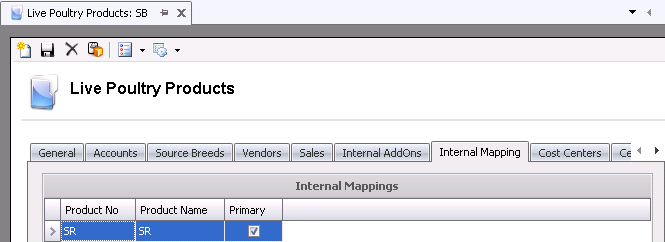

Product groups are used to group products under one target or to be able to enter different weights for one product. The group product is used in BRPA targets. If the same product will be processed at different weights, then a product needs to be created for each weight group and mapped to the original product. The product group must be created in the same manner as Products then mapped using the Internal Mapping tab. This will be used later in the BRPA Master Data>Product Groups to configure further details.

In General>General>Products, create the Product Group as outlined in Products.

Click on the Internal Mapping tab and select the Product No that can be used for the product group.

Select the Primary flag for the source product that primarily sources this product group.

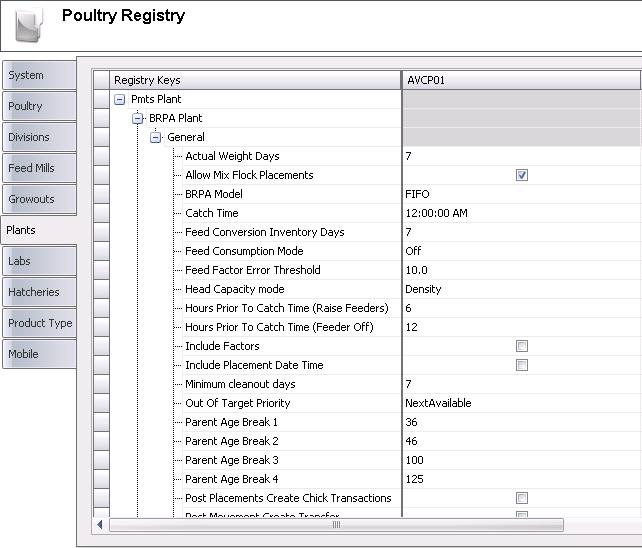

Actual Weight Days – number of days prior to harvest to look for BRIM field weight transactions or process receiving transactions.

Allow Mix Flock Placements – when selected, the program will create flocks with mixed products when necessary. The calculation attempts to maintain flocks of the same product but when it has finished the placements for a day and comes to the final placement number, the program has no option except to split a flock with the remaining products.

BRPA Model – the following options are available as BRPA planning models:

FIFO - first birds in are first birds out.

First pickup thin with lock - when the entity is selected the first time, the entity is thinned by removing birds due to density exceeding the product max density as defined. A lock will be placed on the house/pen so that the projection will not project again until the minimum days after thinned has been met. Minimum days after thinned is defined on the BRPA Product.

Thinning - logic will remove the birds from the house or pen if the density is going to be exceeded or birds are required to meet the target. The entity can be projected any time the birds are required.

Thinning with lock - logic will remove the birds from the house or pen if the density is going to be exceeded or birds are required to meet the target. Once the entity has been selected for projection, the entity cannot be selected again until the minimum days after thinned has been met. Minimum days after thinned is defined on the BRPA Product.

Feed Factor Error Threshold – allowable variance (plus or minus) of projected weight adjusted by feed consumption to be marked as outside range when projecting weights.

Head Capacity Mode – if the 'House Capacity' option is selected, BRPA will utilize this capacity when creating projected placements. Alternately, if 'Density' is selected then the projected placements will utilize the house area and monthly density (area/density) to determine head placed. If no area is entered in the house master, the placement will use house head capacity.

Hours Prior to Catch Time (Raise Feeders) - enter the number of hours prior to catch to raise feeders.

Hours Prior to Catch Time (Feeder Off) – enter the number of hours prior to catch to turn feeders off.

Include Factors - If the Include Factors option is selected and the Weight Mode is set to Percent Deviation, the logic will include the weight factor, farm factor, seasonal factor, breed factor and parent age breed factor when calculating projected weight. When Include Factors options is not selected, only the weight factor will be used to calculate the projected weight. The system uses the house factors first. If there are no house factors defined, then the farm factors will be used. If there are no farm factors defined, the profile factors will be used. If there are no factors defined in any of the above, the registry factors will be used as defined in Admin>System>Registry>Poultry Registry>Plant>BRPA Plant>General.

Include Placement Date Time - When Include Placement Date Time is set to true and Time Precision is set to True, the logic will calculate the total time from the time of the placement to calculate the projected weight. When Include Placement Date Time is set to false, only the date will be used to calculate the projected weight.

Minimum cleanout days – enter the minimum number of days allowed for cleanout.

Out of Target Priority – select one of the following options:

Next Available – will select the flock to be harvested if it exceeds the weight or max product age but select it at the next available target.

Exceed Target – will select the flock to be harvested if it exceeds the weight or max product age even if it is going to exceed the target head.

Parent Age Breaks 1-4 – the BRPA Performance Profile will analyze broiler flock performance based on the age of the breeder parent flock at the time of egg set. These ages are grouped in age ranges. Select the break points for up to four age ranges.

Post Placements Create Chick Transactions – if selected, Post will automatically create a chick transaction for every placement entered.

Post Movement Create Transfer – if selected, Post will automatically create a transfer for every placement with a source entity entered.

Split House Threshold – specify the minimum head inventory for a single house for which BRPA can schedule a split pickup for the house. Any house will less birds than this threshold will be scheduled as a single pickup for the entire house.

Time Precision – if selected, projected weights will calculate to a fraction of a day based on the harvest time.

Truck Capacity Rounding – if selected, the head count of a pen exceeds the truck capacity it will add another truck to pick up the remaining head. If not checked the head count will be added to another pen in the house.

Use Fixed Cycles – if selected, the BRPA will use the specified parameters in BRIM House Master to create brood placements and grow movements when generating projections.

Validate Processing Health Status - if the option is selected, the logic will schedule entities based on the processing control status defined on the Lab Test Code. If the option is not selected, entities will be scheduled without considering the health status.

End of Day - If Lab Test Code>Processing Control Status is set to End of Day and the entity has at least one positive result at the time that the projection is run, the entity will be scheduled to be processed at the end of the processing day.

End of Week - If Lab Test Code>Processing Control Status is set to End of Week and the entity has at least one positive result at the time that the projection is run, the entity will be schedules to be processed at the end of the processing week.

Weight Factor Error Threshold – Allowable variance (plus or minus) of projected weight adjusted by test weight to be marked as outside range when projecting weights.

Weight Mode – select from one of the following options:

Percent Deviation – calculates the bird weight using all factors for the same age as the actual weight captured then it calculates the % deviation from the actual and applies the same deviation to the kill age projection.

Daily Weight Gain – is recalculated based on the actual weight captured and then the new weight gain per day is used moving forward to create the kill age projection.

Weight Mode Priority – select from one of the following options:

Processing Transaction and Field Transactions – will always utilize the most current transaction closest to Harvest date.

Field Transactions Only – utilizes only field transactions.

Processing Transaction Only – utilizes only processing transactions.

Processing Transactions then Field Transactions – utilizes the processing transaction before factoring field transactions.

None – will bypass the logic and no weight will be used.

Weight Projection Mode - determines how the standard weight is applied to the entity.

Date Sold – the standard weight and total weight gain to harvest will be calculated up to the date sold age.

Date Sold Minus One – the standard weight and total weight gain to harvest will be calculated up to the date sold age minus one day.

Farms will be set up during BRIM implementation. There are some tabs on the farms that must be completed for the BRPA module to project processing schedules. Optionally, if the factors are determined by house or pen, the values can be defined at that level. If you have multiple plants and only certain farms can be processed at specified plants, you will set this up in the farm master.

The following components are outlined in the BRIM Farms>BRPA tab:

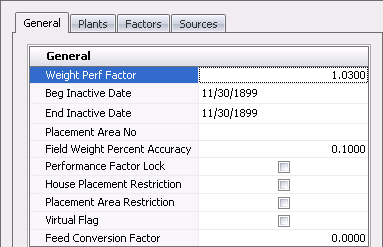

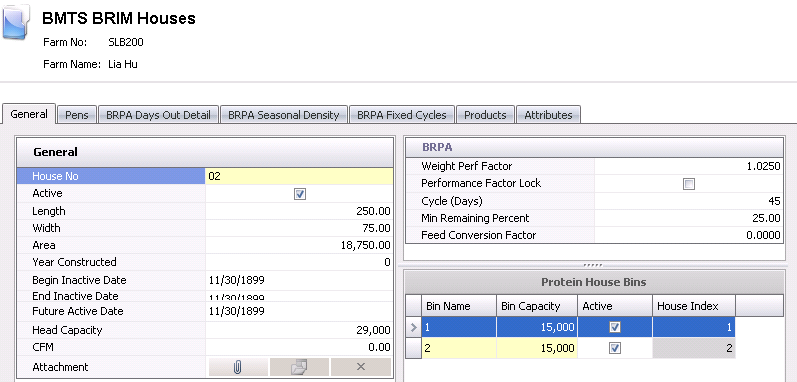

The General tab indicates the performance factors for the farm.

Weight Perf Factor – is a farm level calculation of weight performance based on historical factors. This value can be overridden. The value represents the farm’s performance against the average. For example, if the value here is 1.025, this farm has performed at 2.5% of the average or slightly better than average.

Beg Inactive Date – represents the date that the farm becomes inactive and is not available for placement.

End Inactive Date – represents the date that the farm is no longer inactive and is again available for placement.

Placement Area No – allows the user to define a placement area to be used in planning.

Field Weight Percent Accuracy – optional field to enter the average accuracy of the farm weights recorded in field transactions. For example, if a value of '0.1' is entered and the farm weights entered in field transactions is '4.0', then BRPA will project the weight as '4.4' as on average the farm weigh 10% lighter than the actual processing weight.

Performance Factor Lock – when selected, this prevents the factors from being modified when the Calculate Factors function is generated. The factors may still be modified manually.

House Placement Restriction – indicates that the farm has a house placement restriction due to bio-security or another reason.

Placement Area Restriction – indicates that the farm has an area placement restriction due to bio-security or another reason.

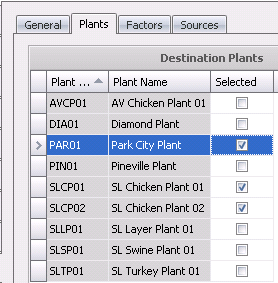

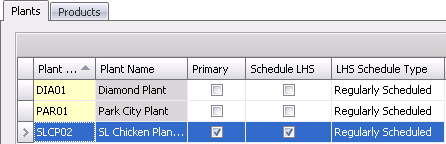

The Plant tab indicates the plants that the farm ships to. If the primary plant is not available, the BRPA will select another plant to process the birds. If there are farms selected on this tab, the birds can only be shipped to the selected plants. BRPA will prioritize the plant based on the closest plants as defined on the Distances tab. If there are no options selected on this tab, then the birds can be processed at any plant. BRPA will prioritize based on the closest plants as defined on the Distances tab.

Plant No – indicates the plant that the farm ships to.

Plant Name – displays the name of the plant.

The Selected flag – indicates that the farm can be used to supply products to the plant that is selected. De-select the flag if the plant is no longer used.

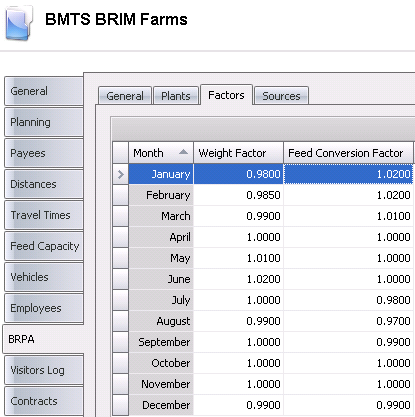

The Factors tab allows the seasonal weight factors and feed conversion factors to be defined by farm. These factors will be used if House Factors have not been defined. The system uses the House Factors first, if no House Factors are defined then Farm Factors will be used. The system uses the house factors first. If there are no house factors defined, then the farm factors will be used. If there are no farm factors defined, the profile factors will be used. If there are no factors defined in any of the above, the registry factors will be used as defined in Admin>System>Registry>Poultry Registry>Plant>BRPA Plant>General.

Month – displays the month that is being factored.

Weight Factor – displays the seasonal factor for weight of the birds at the farm. The values are entered as 0.9800 for birds that have a seasonal factor or 98% below the target or 1.0200 for the birds that are 2% over the target.

Feed Conversion Factor - displays the seasonal factor for the farm for feed conversion. The values are entered as 0.9800 for birds that have a seasonal factor or 98% below the target or 1.0200 for the birds that are 2% over the target.

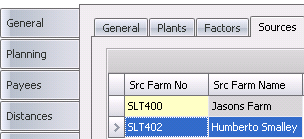

The Sources tab is used for two-stage broiler operations where birds are transferred from a brood farm to a grow farm, usually noted in turkeys. The source brood farms are defined on this tab for planning future placements.

Src Farm No – indicates the source brood farm.

Src Farm Name – displays the name of the farm.

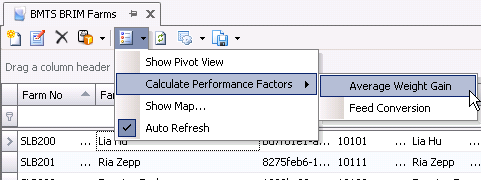

In the BMTS>BRIM Farm Master List View, there is an option to calculate the Performance Factors. This includes all of the flocks with the following criteria:

Last Date Sold Between Date Range specified in the dialog

Must be closed or inactive

Not flagged with BRPA excluded

Plant specified in the farm (primary plant) will match the plant entered in the dialog

Optionally match to a product

The filters above are used to get the Processing Transactions to calculate the Average Weight and divide by Age to get Average Weight Gain. If the calculation is for feed conversion, all the feed deliveries for the flocks that matched the criteria above will also appear. The threshold is used to exclude the top and lowest percent to calculate the median. Median Average Weight Gain gets a Performance Factor of 1, and the rest gets below or above 1.

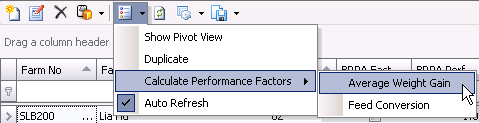

From the menu Options  button, select Calculate Performance Factors.

button, select Calculate Performance Factors.

Select the performance factor that is being calculated, either Average Weight Gain or Feed Conversion.

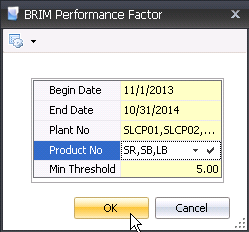

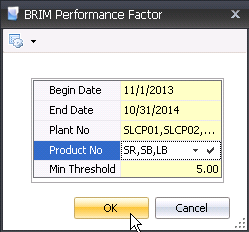

In the dialogue, enter the following data:

Enter the Begin Date.

Enter the End Date.

Select the Plant No. This will create all of the performance factors for farms assigned to the selected plants.

Enter the Min Threshold – percentage of lower and upper values ignored by calculation.

Select OK

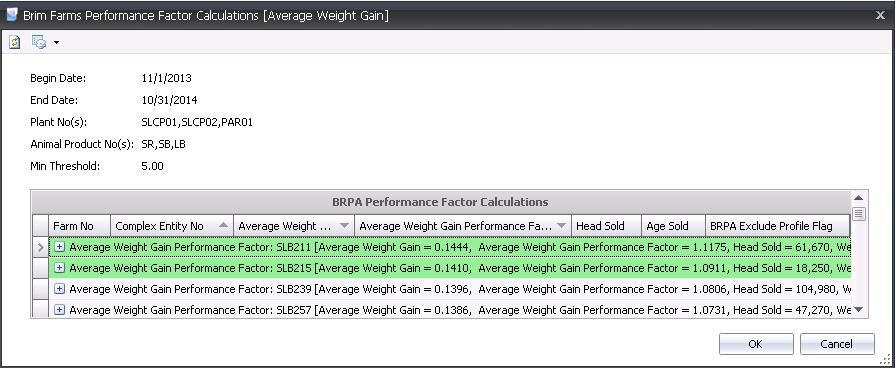

Dialog will open and is sorted by the Performance Factor.

Performance Factors will be identified with the following color codes:

No Color - farm is producing within the defined Min Threshold. Farms are average performing farms.

Green - farm is performing in the top percentile of the defined Min Threshold. These are the best performing farms.

Yellow - farm is the median of the Min Threshold.

Red - farm is performing in the bottom percentile of the defined Min Threshold. These are the poorest performing farms.

Click OK to save and update the profile information.

BRIM Houses are set up during BRIM implementation. Weight and performance factors can be defined for the house or if there are seasonal factors, the factors can be determined by month.

The following components are outlined in the BRIM Houses section:

The General tab is used to enter the basic details for the house as well as the basics that are required for BRPA. Weight and performance factors can be defined for the house or if there are seasonal factors, the factors can be determined by month.

In regards to BRPA factors, the system uses the house factors first. If there are no house factors defined, then the farm factors will be used. If there are no farm factors defined, the profile factors will be used. If there are no factors defined in any of the above, the registry factors will be used as defined in Admin>System>Registry>Poultry Registry>Plant>BRPA Plant>General.

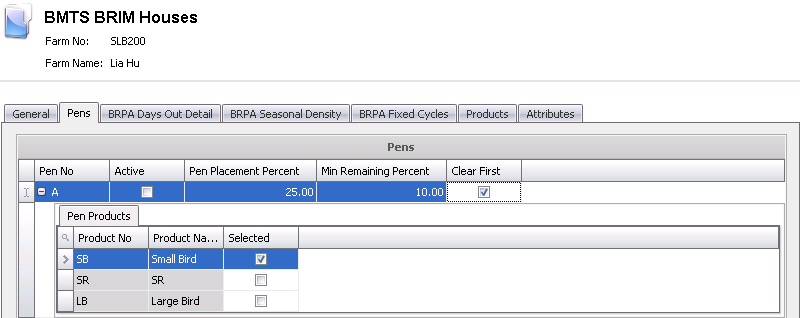

The Pens tab is used to specify the product that is to be placed in the pen, if the BRPA factors are determined at the pen level.

Click the  button

to add a new pen line.

button

to add a new pen line.

Pen No – enter a unique code to identify the pen (alphanumeric, max 100 characters). Click the child grid in the Pen No field for a list of pen products. Checking the Selected flag will allow the pen to be utilized as any or all of the flags that are selected. Pen products are identified in: General> General> Products>Animals>Poultry.

Select the Active flag if the pen is currently active.

Pen Placement Percent – enter the percentage of the head placed.

Min Remaining Percent – used to calculate the minimum remaining head that can be left in the pen when Brpa projection is run.

Clear First - Indicates that this pen is cleared before the others.

Click on the child grid to display a list of products. Select the products that can be placed in this pen.

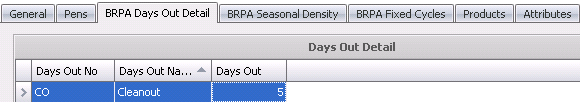

Days Out Detail defines the periods where the farms are not available for placement. Days Out codes are user defined according to the requirements of the customer.

to add a new line detail.

to add a new line detail.

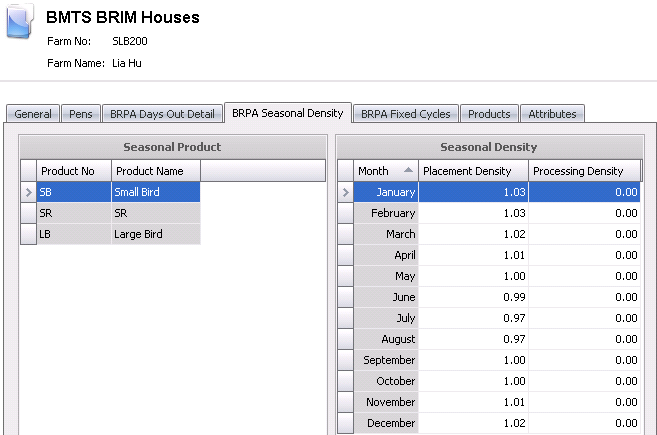

The BRPA Seasonal Density tab is used to enter the seasonal density and processing density for each product that can be placed or harvested in the house.

In the Seasonal Product grid, click on the Product No that requires the seasonal factors to be entered.

For each month, enter the seasonal factor for Placement Density based on birds placed/ft2 or birds placed/m2.

Enter the Processing Density for each month based on the desired lbs/ft2 or kgs/m2 to be processed.

Repeat this process for each product that can be placed in the house.

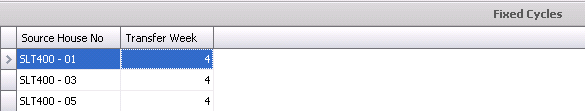

The BRPA Fixed Cycles tab is only used for multi-stage operations where the birds are transferred from brood to grow. This option associates the brood and grow farms so that the sources for the entity can be defined.

Click

to add a

new source house.

to add a

new source house.

From the Source House No field, select the house from where the product will be sourced.

In the Transfer Week field, enter the week that the product will be transferred.

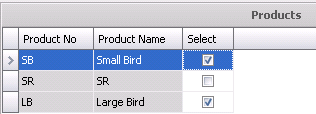

Products is an optional list of products to place in a house. Usually they are not selected unless there are product placement restrictions for the house. If selected, only the products checked will be placed in the house. The information in the fields will default in.

Product No indicates the house product.

Product Name displays the name of the product.

Check the Select flag if the product in the house can be used as one or all of the products.

This options includes all of the flocks with the following criteria:

Last Date Sold Between Date Range specified in the dialog

Must be closed or inactive

Not flagged with BRPA excluded

Plant specified in the farm (primary plant) will match the plant entered in the dialog

Optionally match to a product

The filters above are used to get the Processing Transactions to calculate the Average Weight and divide by Age to get Average Weight Gain. If the calculation is for feed conversion, all the feed deliveries for the flocks that matched the criteria above will also appear. The threshold is used to exclude the top and lowest percent to calculate the median. Median Average Weight Gain gets a Performance Factor of 1, and the rest gets below or above 1.

From

the menu Options  button, select Calculate Performance

Factors.

button, select Calculate Performance

Factors.

Select the performance factor that is being calculated, either Average Weight Gain or Feed Conversion.

In the dialogue, enter the following data:

Enter the Begin Date.

Enter the End Date.

Select the Plant No. This will create all of the performance factors for farms assigned to the selected plants.

Enter the Min Threshold – percentage of lower and upper values ignored by calculation.

Select OK

Dialog will open and is sorted by the Performance Factor.

Performance Factors will be identified with the following color codes:

No Color - house is producing within the defined Min Threshold. Houses are average performing houses.

Green - house is performing in the top percentile of the defined Min Threshold. These are the best performing houses.

Yellow - house is the median of the Min Threshold.

Red - house is performing in the bottom percentile of the defined Min Threshold. These are the poorest performing houses.

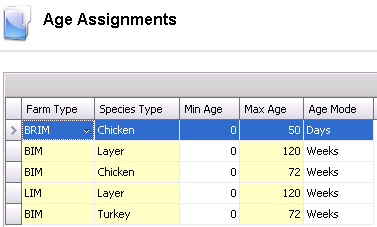

The age assignment will be used in the Weight Performance Curve. It will set the beginning and end date for the average weight gained per day as well as the % daily mortality.

In Admin>Business>General>Definitions, select Age Assignments. Required fields are outlined below.

Click the  button.

button.

Select the Farm Type.

Select the Species Type.

MIn Age is optional to identify the minimum age that the birds can be processed.

Enter the Max Age birds are to be processed.

Select the Age Mode. Available options are: Days, Weeks or Event.

The Master Data section contains two components:

Once Products and Product Groups have been created in General>Products>Animals>Poultry, the parameters to be used when calculating the projections can be defined.

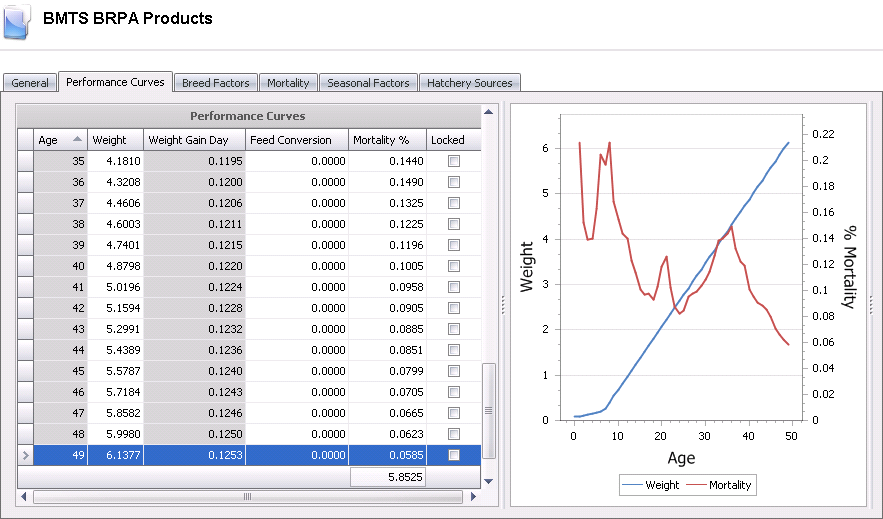

There are six tabs in the Products section:

In BMTS>BRPA>Master Data, select Products.

Click

the  button

and then click on

the drop-down arrow and select the product to be set up.

button

and then click on

the drop-down arrow and select the product to be set up.

Specify the parameters to be used for calculating the projections in the required tabs.

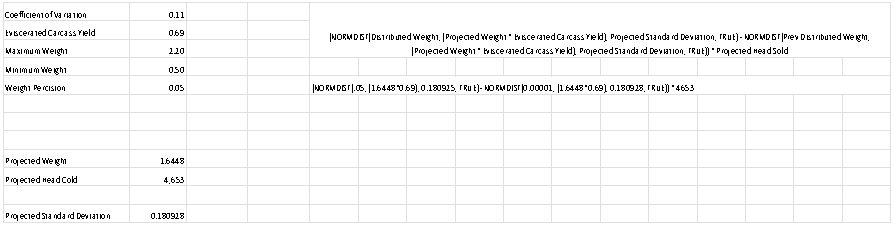

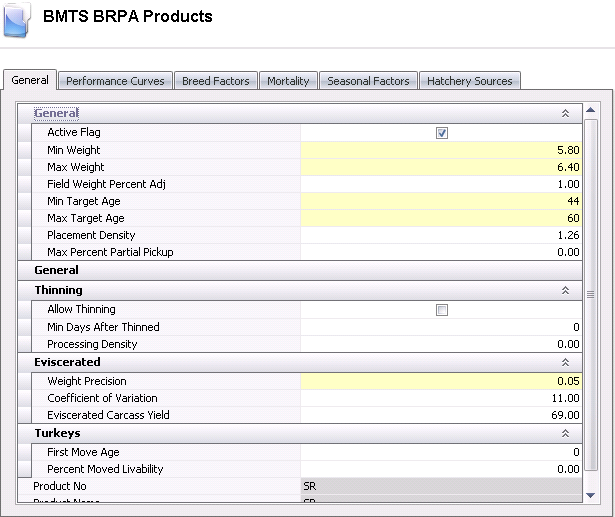

The General tab is used to enter the basic details for the product profile. The parameters are entered for not only the product but for all the products groups if they will be used. The Min and Max weight need to be a range wide enough to include the weights of all the product groups that will be used in the profile and on the targets.

The Thinning section on the General tab determines if thinning is used in the production cycle and if used, defines the parameters to be used for thinning.

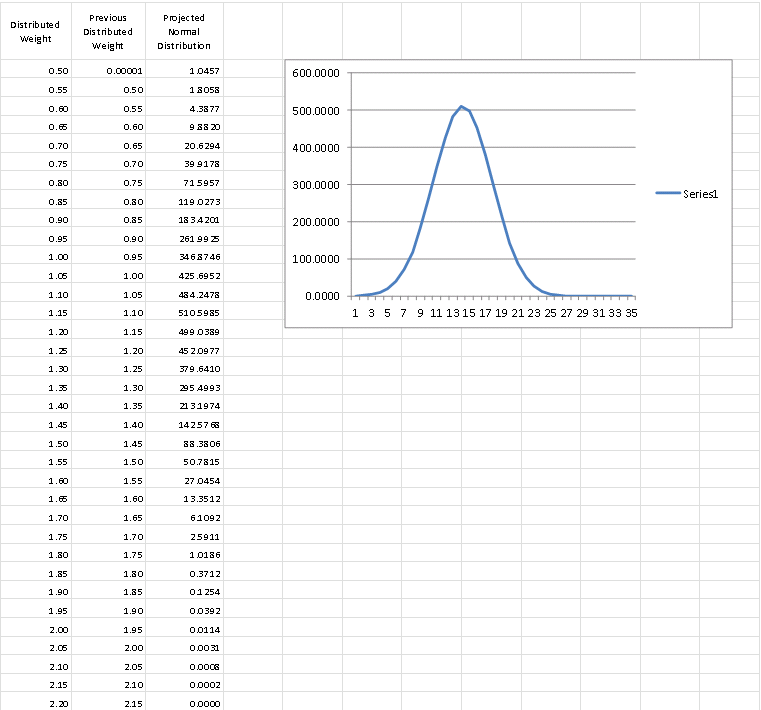

The Eviscerated section will be used to determine how the graphs will be displayed after a projection is calculated.

The Performance Curves is the location where the daily factors for weight, feed conversion and mortality are entered. The factors can be entered manually, calculated from performance or import breeder standards. There is an option to lock the factors for each day to prevent future modification to calculated statistics. These factors will be used if House Factors have not been defined. The system uses the House Factors first, if no House Factors are defined then Farm Factors will be used. The system uses the house factors first. If there are no house factors defined, then the farm factors will be used. If there are no farm factors defined, the profile factors will be used. If there are no factors defined in any of the above, the registry factors will be used as defined in Admin> System> Registry> Poultry Registry> Plant> BRPA Plant> General.

Users can manually add the data to the following columns:

Once the Product parameters have been set, it is time to calculate the performance curves and factors to be used during the projections. This includes all of the flocks with the following criteria:

Last Date Sold Between Date Range specified in the dialog

Must be closed or inactive

Not flagged with BRPA excluded

Plant specified in the farm (primary plant) will match the plant entered in the dialog

Optionally match to a product

The filters above are

used to get the Processing Transactions to calculate the Average Weight

and divide by Age to get Average Weight Gain. If the calculation

is for feed conversion, all the feed deliveries for the flocks that matched

the criteria above will also appear. The

threshold is used to exclude the top and lowest percent to calculate the

median. Median

Average Weight Gain gets a Performance Factor of 1, and the rest gets

below or above 1.

In BMTS>BRPA>Master Data, select Products.

Right-click on a product and select `Calculate Profile` or open the product and select Options>Calculate Profile.

Once the calculation has completed, double-click on the product that was just calculated and click on the Performance Curves tab. If the curve is not feasible due to there not being enough history data in the program, the fields can be edited as desired.

If the values are to be preserved, select the Locked option.

Open the product and select Options>Load from Primary Breeder Standards.

In the dialogue, select the following parameters:

Standard File Name - select the applicable standard from the list of available options.

Sex - select the required sex for the product. Options available will be Male, Female or Straight Run.

Measurement - select if the data is to be imported with US or Metric values.

Click OK to import the standards.

If the values are to be preserved, select the Locked option.

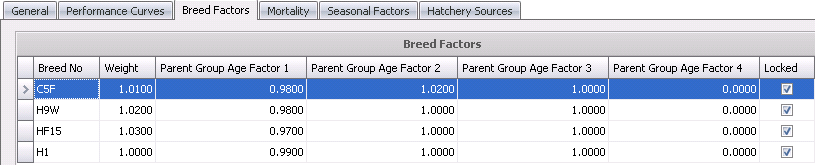

Breed Factors is an optional screen to enter any variables for the breeds assigned to the product. The breed factors are entered for the breed and also an option to enter the factors based on the age of the parent flocks. Parent Age Groups are set up in Registry>Plants>PMTS Plant>BRPA Plant>General>Parent Age Break 1, 2 and 3. There is an option to lock the factors so that they will not be updated with the BRPA calculation option.

Select the Breed No from the list of available breed codes.

Enter the Weight factor. The value will be entered as 0.98 for breeds that perform 2% under the average and 1.02 for breeds that perform over the average.

Enter the Parent Age Factors as required. The value will be entered as 0.98 for breeds that perform 2% under the average and 1.02 for breeds that perform over the average.

Select the Locked option is the values are not to be modified when new performance data is calculated. Leave the option unchecked if the values are to be overridden with new performance data.

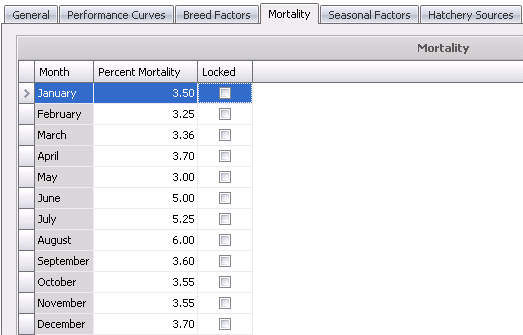

Mortality is an optional screen to enter monthly mortality to adjust processing head based on seasonality mortality factor. This screen is only needed if using Standard Mortality or if no actual mortality is found for the flock. There is an option to lock the factors so that the factors will not be adjusted when the BRPA calculation option is generated. This screen should be completed if the Mortality Calculation Mode in the profile is set to Seasonal Monthly Percent - Mortality is calculated from the weight performance profile (monthly statistics). No actual data is used.

Enter the Percent Mortality based on the month that the entity is sold. The value will be entered at 5.0 for 5.0%.

If the factors are not to be updated based on performance, select the Locked field. If the values are to be updated with performance data, leave the option unchecked.

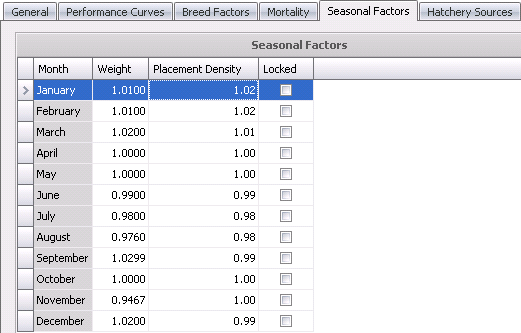

Weight and placement density can be entered on a monthly basis to add a seasonality factor to the processing equation. The seasonal factor is based on the sold date of the entity. The factors can be locked so that the values are not updated when the BRPA calculation option is generated.

Enter the Weight factor based on the month that the birds are sold. The value will be entered as 0.98 for breeds that perform 2% under the average and 1.02 for breeds that perform over the average.

Enter the Placement Density factor based on the month that the birds are sold. The value will be entered as 0.98 for breeds that perform 2% under the average and 1.02 for breeds that perform over the average.

If the factors are not to be updated based on performance, select the Locked field. If the values are to be updated with performance data, leave the option unchecked.

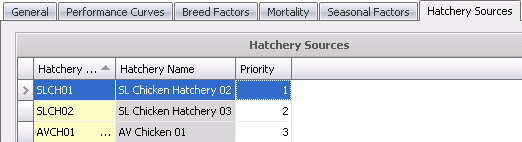

Hatchery Sources define the hatcheries that produce the product and assign a priority to the hatchery to establish the preferred sources.

Select the optional Hatchery No.

Set the Priority with 1 being the highest priority.

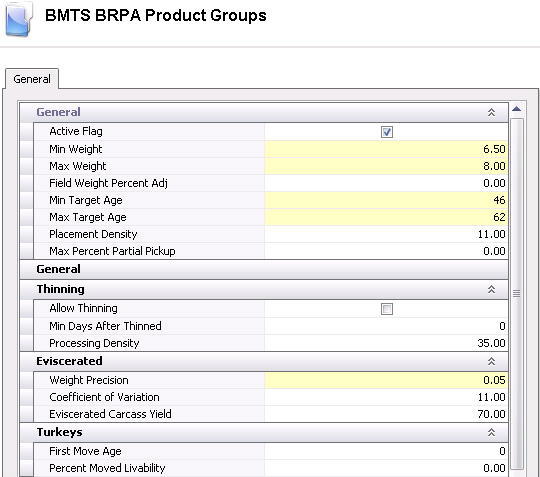

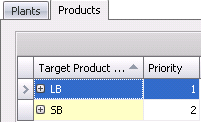

Product Groups allow the placement product to be different that the processing target. Targets are established based on the product group. For example, the placement product may be Broiler Straight Run (SR), however it may be processed as Large Bird (LB) and Small Bird (SB). The Product Groups are initially configured in General>Products>Animal>Poultry by creating a new product. Further details can be viewed in Product Groups. Once the Product Group is created, the product is configured in BRPA Product Groups for planning.

to

add a product.

to

add a product.The General grid is used to enter the basic details for the product profile. The parameters are entered for not only the product but for all the products groups if they will be used. The Min and Max weight need to be a range wide enough to include the weights of all the product groups that will be used in the profile and on the targets.

Active Flag – will default as selected indicating that the product is active. If the product is no longer required, uncheck this option.

Min Weight - enter the minimum weight to be processed in lbs or kgs.

Max Weight - enter the maximum weight to be processed in lbs or kgs.

Min Target Age - enter the minimum target age to be processed in days.

Max Target Age - enter the maximum target age to be processed in days.

Placement Density – optional; only needed for BRPA to plan placements based on density.

The Thinning section on the General tab determines if thinning is used in the production cycle and if used, defines the parameters to be used for thinning.

The Eviscerated section will be used to determine how the graphs will be displayed after a projection is calculated.

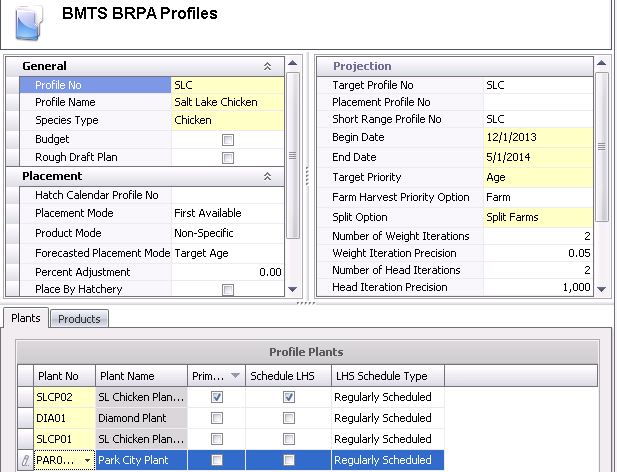

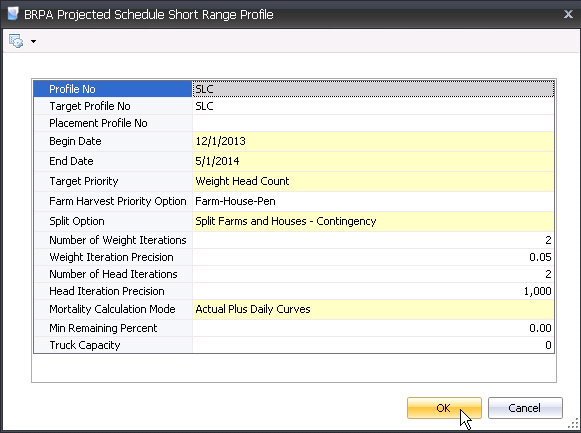

Profiles are used to create different processing scenarios. Profiles are created by species and have the required plants assigned to the profile. BRPA profiles will be used to set up targets for the products and or different product groups. At least one profile is required; however you are able to create multiple profiles.

In BMTS>BRPA>Master Data, select Profiles.

Create a new profile by clicking the

button.

button.

Enter the Profile No. Alphanumeric, max 20 characters.

Enter the Profile Name to describe the profile. Alphanumeric, max 40 characters.

Select the Species Type. Options will be Chicken or Duck.

Select the Budget option if the data generated from the process is related to the budgeting process. FDSA will ignore any placements associated with profiles with the Budget option selected.

If Rough Draft is selected, the user can copy a projected schedule to a rough draft pr

Optionally, a different Target Profile can be selected if the targets are sourced from a different profile. If this field is left blank, the targets will be created by the profile currently being defined.

A different Placement Profile can be selected if the placements are sourced from a different profile. If this field is left blank, the placements will be created by the profile currently being defined.

The Short Range Profile can also be selected from a different profile if desired. This is generally only used when defining long range profiles and the long range is to begin from where the short range projection ended.

Enter the Begin Date for the start of the projection.

Enter the End Date for the last day of the projection.

Select the Target Priority to determine the priority for the birds to be processed. Options are Age, Head Count, Head Count and Weight or Weight.

The Farm Harvest Priority Option determines how the birds are sourced from the farms. The Farm Harvest Options are dependent upon the Target Priority selected. This field is optional with the following options:

Farm - farms are prioritized based on the highest average target priority to the lowest average target priority. Houses within the farm are prioritized from the highest average target priority to the lowest average target priority.

Farm-House-Pen - farms are prioritized based on the highest average target priority to the lowest average target priority. Houses and pens are then assigned in numerical order.

None - houses and pens are prioritized based on the highest average target priority. Farm average target priority are not taken into consideration.

The Split Option is a required field that determines how the houses are to be split. Options are:

No Split – farms and or houses will not have split pickup days.

Split Farms – The farm can have split pickup days.

Split Farms and Houses - At all Times – farms and houses can have split pickup days.

Split Farms and Houses - Contingency – farms and houses will have split pickup days as needed.

Number of Weight Iterations is used to enter the number of iterations the system is allowed to make in order to reach the projected weight. Note that if the Target Priority is set to Age, the number of weight iterations is not required.

Weight Iteration Precision is used to enter the spread in the weight that the system is allowed to make in order to reach the projected weight. For example, if the value of 0.05 is entered, the process will pick up all weights that are higher or lower than the target weight by 5%. Note that if the Target Priority is set to Age, the weight iteration precision is not required.

Number of Head Iterations determines the number of iterations the system is allowed to make in order to reach the projected head count.

Head Iteration Precision defines the variance allowed in the head count for system to reach the projected head count. For example, if the value of 1,000 is entered, the process will pick up all head counts that are higher or lower than the target head count by 1,000.

Mortality Calculation Mode selects the mode that the system will use to project mortality. Available options are:

Actual Plus Daily Curves – Mortality is calculated using actual data (Field Trans) plus projected daily mortality from the curve defined in weight performance profile to harvest day.

Seasonal Monthly Percent – Mortality is calculated from the weight performance profile (monthly statistics). No actual data is used. Mortality is entered in BRPA Products>Mortality tab.

Standard Daily Curves – Mortality is calculated using only the daily mortality curve defined in weight performance profile. Mortality is entered in the BRPA Product>Performance Curves.

Field Trans Weight Adjustments determines if field transaction weights are to be included or excluded from projections. Options are Include or Exclude.

Min Remaining Percent determines the percentage of birds that can be left in the house or pen for BRPA projections.

In the Truck Capacity field, enter the number of head the truck can haul. This number will only be used with the thinning logic.

Use Carry Over Logic takes into account previous projections during the week and adjusts the projection to fulfil a weekly total. For example, the target is 100,000 birds per day for 5 days per week. The projection for Monday is 92,000 head and the projection for Tuesday is 94,000 head. The total amount of carry over for the two days is 14,000 head. The carry over can be either positive or negative.

to add a plant to the profile.

to add a plant to the profile.

to

add a BRPA product to the profile.

to

add a BRPA product to the profile.

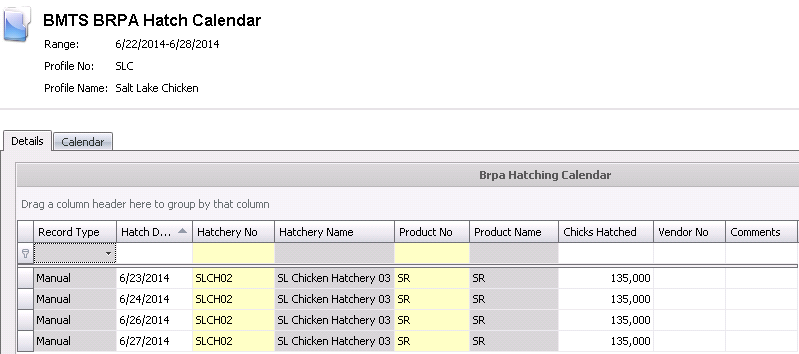

BRPA Planning has three sections that are used to calculate projections.

The Hatching Calendar is used or calculated based on the following:

to

add a new detail line.

to

add a new detail line.

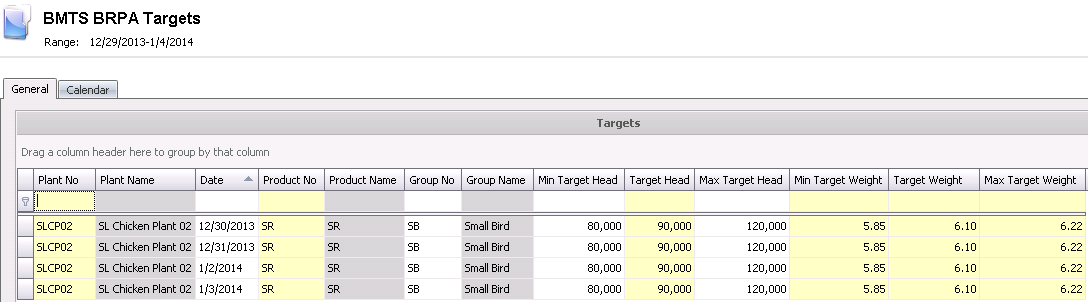

Targets will be used with the weight curves during the calculation to determine the day for each house to be processed. Targets are entered daily based on the plant requirements.

In BMTS >BRPA>Planning, select Targets.

Click the

button.

button.

Select the profile.

When the BRPA Target Screen appears, select  to add

the targets.

to add

the targets.

Select the Plant No.

Enter the Date for the target.

Select the target Product No.

If using product groups, select the Group No.

Optionally, enter the minimum target head in Min Target Head.

Enter the desired target head in Target Head.

The maximum target head can be optionally entered in Max Target Head.

Enter the minimum target weight in Min Target Weight.

Enter the desired target weight in Target Weight.

Enter the maximum target weight in Max Target Weight.

Repeat process to enter targets manually or select Options>Copy to use the Copy feature.

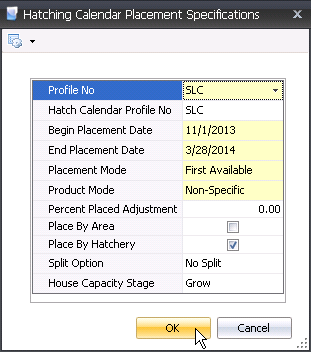

Movements is the tool used to plan the placements. The placements can be calculated using the Calculate option or, alternatively, manually created. When the planned movements are posted, the entities are automatically created and available for actual placement. The Movements are sourced from the available chicks as defined in the Hatching Calendar.

The Calculate option plans the movements based on the Hatching Calendar. If the Hatching Calendar is not defined, the calendar will be derived from the Targets prior to the planning the movements.

option.

option.No Split – farms and or houses will not have split pickup days.

Split Farms – The farm can have split pickup days.

Split Farms and Houses - At all Times – farms and houses can have split pickup days.

Split Farms and Houses - Contingency – farms and houses will have split pickup days as needed.

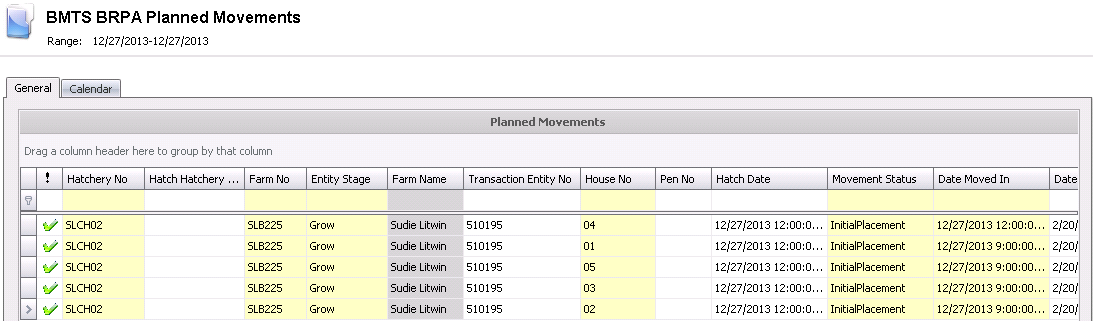

In BMTS >BRPA>Planning, select Movements.

Click the

button.

button.

Select the profile.

When the BRPA Planned Movements edit screen

appears, select

to

add the placements or movements.

to

add the placements or movements.

Select the Hatchery No for the hatchery that is sourcing the chicks.

Select the Hatch Hatchery No if the chicks are hatched at a different hatchery than sourced.

Select the Farm No where the chicks will be placed.

Select the Entity Stage. Broilers will generally select Grow. Commercial Turkeys will select Brood for the Placement and Grow for the Movement.

Depending on the Entity Number Mode defined in Registry>Growouts>BRIM/TIM Growout>General, the Transaction Entity No will be automatically derived, otherwise the field will be manually populated.

Select the House No that the entity will be placed.

If the granularity is FFHP, select the Pen No. If the granularity is FFH, this field is not used.

Enter the Hatch Date that the chicks will be hatched.

The Movement Status will default to Initial Placement. The other option is Additions which is used for transfers from brood to grow for turkey operations.

Enter the Date Moved In which represents the placement date for Initial Placements or the moved in date for transfers from brood to grow.

Enter the Date Moved Out. This will represent the processing date for details where the Entity Stage = Grow. For detail lines with the Entity Stage = Brood, the Date Moved Out will represent the date that the entity is moved from brood to grow. The Date Moved Out will be automatically calculated based on the Target Age entered on the product.

Enter the Head Placed. For transfer transactions, the Head Placed will represent the head moved from brood to grow.

Select the Product No for the product that is to be placed.

The Formula Assignment No can optionally be assigned if formula assignments are assigned by entity. Otherwise, the formula assignment will be derived based on the product.

Target Head Count Steps determines how the entity is selected for processing. The default is Area. Other options are First, Second or Final.

The Source Complex Entity is selected when the birds are being transferred from brood to grow. The brood entity will be the source of the selected grow entity.

Area is derived from the house that the entity is being placed.

The Planned Density is calculated based on the BRPA Head Placed / Area.

The Actual Density is calculated initially based on the Planned Density and recalculated when the entity is actually placed.

If the placement is being purchased from external sources, select the Vendor No for the vendor supplying the chicks.

Optionally, the Complex PO No for the vendor for the purchase can be selected.

Repeat the process manually for all planned placements.

Posting Movements will create the entity in BRIM>Master Data Entities.

The BRPA Projections has two types of projections:

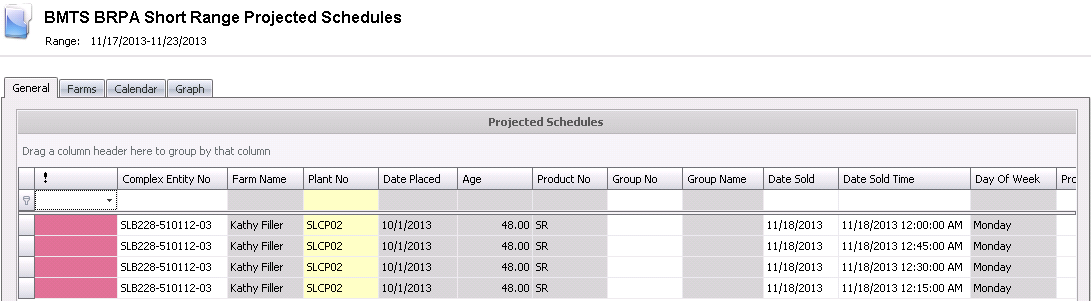

The Short Range Forecast is based on actual flocks that have been placed on the BRIM Farm. Once the planned processing schedule has been calculated. The user may modify the data as required. Posting the short range is used for FDSA purposes.

Before Short Range can be calculated, a base or starting point for the short range must be created. This can be done by a manual entry or by using the import feature. These methods are only done the first time a Short Range is created.

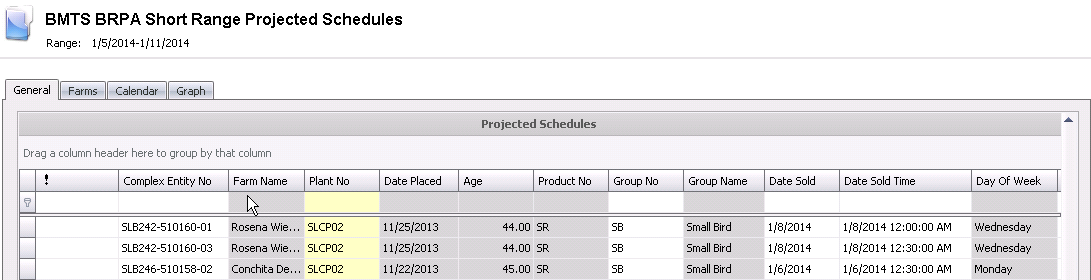

In BMTS>BRPA>Projections select Short Range.

In the Short Range main index, click New>Default to create a record.

In the Profiles dialog box, select the profile from the Profile No drop-down menu and then click 'OK'.

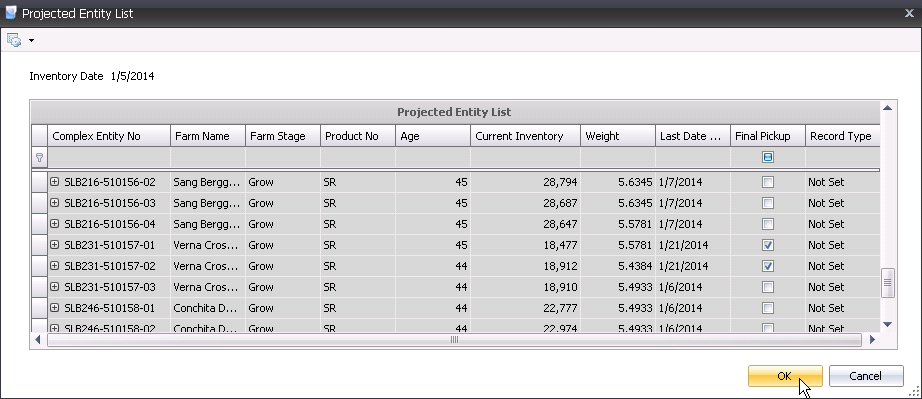

In the Short Range Projected Schedules screen, click to add a new line. The Projected Entity List will appear.

From the entity list, select the row to highlight the entity or select multiple entities by holding the Ctrl key down while selecting the entities.

Click 'OK' and entities will be moved to the Projected Schedule screen.

Save and close the record. The record will be moved to the Short Range main screen.

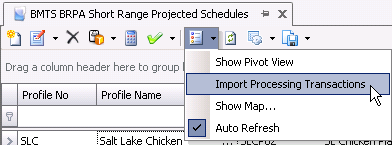

The Import Short Range function builds the kill schedule based on processing trans. The import function matches the processing schedule to the actual processing transactions allowing the user to begin with new processing dates.

In

the Short

Range main index, click the  button and select 'Import Processing Transactions'.

button and select 'Import Processing Transactions'.

In the Import Processing Transactions dialog box, from Profile No, select the required profile.

Select the Begin Date and End Date and then click 'OK'.

The processing records for that time period will be brought into Short Range as the starting point for future processing schedules.

The Short Range Projection is based solely on actual placements and will only plan processing for those placements. The Short Range screen must have at least one entry before the processing schedule can be calculated. The following topics are covered in this section of the document.

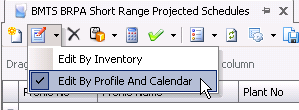

In BMTS>BRPA>Projections, select Short Range.

In the Short Range main index,

click  to calculate the processing schedule.

to calculate the processing schedule.

From Profile No, select the profile that the processing plan will be saved to.

Select the Target Profile No that will determine the targets for the projection.

Select the Placement Profile No that will be used for the calculation.

Enter the Begin Date for the projected processing plan. The Begin Date will be the first date that birds are processed.

Enter the End Date for the projected processing plan. The End Date will be the last date that birds are processed.

Select the Target Priority to determine the method that the birds are selected. Options are Age or Weight Head Count.

Select the Farm Harvest Priority Option to determine how the farms are picked up and delivered to the processing plant. Available options are:

Farm – farms are prioritized based on average weight from highest to lowest. Houses and pens are scheduled based on the heaviest average weight from the highest to lowest.

Farm-House-Pen – farms are prioritized based on average weight from highest to lowest. Houses and Pens are then scheduled in numerical order.

None – houses and pens are scheduled from highest to lowest weight (not farm specific)

Select a Split Option to determine if or how placements can be split. Available options are:

No Split – Placements will not be split.

Split Farms – elect this option if the placement to the farm can be made in split over more than one processing date.

Split Farms and Houses at all Times – farms and houses can be split over more than one processing date.

Split Farms and Houses - Contingency – farms and houses will have split delivery days as needed.

Enter a Number of Weight Iterations to determine the number of loops the system will make to reach the desired target for weights.

Enter the Weight Iteration Precision to define the weight increment for the weights that are picked up in each processing loop.

Enter a Number of Head Iterations to determine the number of loops the system will make to reach the desired target for head counts.

Enter the Head Iteration Precision to define the head increment for the head that are picked up in each processing loop.

Select the Mortality Calculation Mode to determine how mortality will projected. Available options are:

Actual Plus Daily Curves – Mortality is calculated using actual data (field transactions) plus Projected Daily Mortality from the curve defined in weight performance profile to harvest day.

Seasonal Monthly Percent – Mortality is calculated from weight performance profile (monthly statistics). No actual data is used.

Standard Daily Curves – Mortality is calculated using the daily mortality curve defined in the weight performance profile.

Enter a Min Remaining Percent to calculate the minimum head that can be left in the house or pen when BRPA Projections is ran.

Enter a Truck Capacity – optional field used to define the number of birds that can be hauled on the truck. This number will be used in LHS to determine the number of crates to be used.

Click 'OK' and the Short Range will be created.

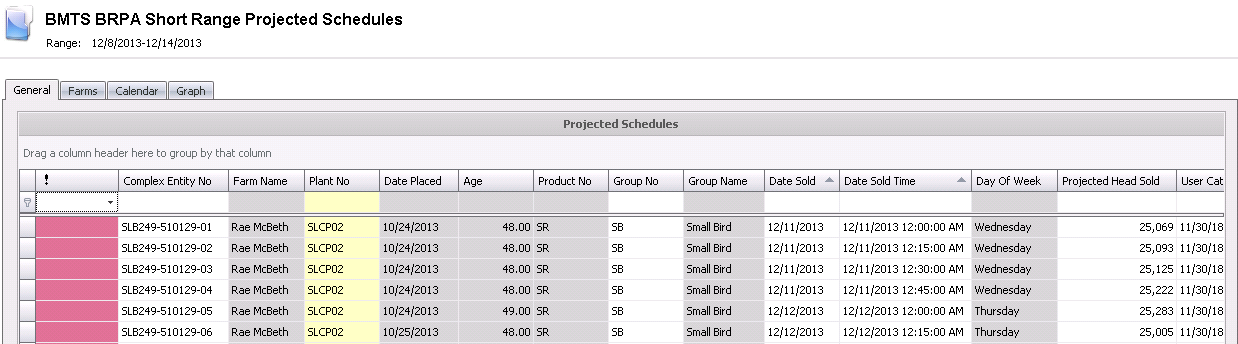

This section is comprised of the following tabs:

Adjustments can be made as needed after the short range has been created. *Note: System generated short range: Once the week has been posted changes are not allowed unless the entire week is un-posted. Then the system will start with the last fully posted week and then recalculate from that week forward.

button.

button.

The General tab contains the data that is relevant for the process of creating a processing schedule.

Processing Order Sequence – displays the order that the entities are processed, and can be edited if required.

Complex Entity No – identifies the Farm-Entity-House-Pen No's, and can be edited if required.

Farm Name – displays the name of the farm.

Plant No – identifies the processing plant that the birds will be going to, and can be edited if required.

Date Placed – identifies the date the birds were placed at the farm.

Age – identifies the age of the bird when sent to the processing plant.

Product No – identifies the product being processed

Group No – indicates the group if the product target was assigned to a user defined group, which allows the products to be grouped together for processing. For example, a group may be all products within a certain weight range. This field can be edited if required.

Group Name – displays the name of the group.

Projected Head Sold – identifies the number of head going to the processing plant, and can be edited if required.

Head Placed – represents the head placed for the entity.

Head Inventory – displays the number of head at the farm, and can be edited if required.

Date Sold – identifies the date the birds are targeted to be sold, and can be edited if required.

Date Sold Time – displays the date and time that the entity was sold

Day of Week – displays the day of the week that the entity was sold.

Projected Average Weight – displays the projected average weight for the entity being processed. This field can be edited if required.

Target Weight – displays the target weight per age as defined in Products>Performance Curves. This field can be edited if required.

Weight Variance – displays the difference between the Projected Average Weight and the Target Weight.

Final Pickup – this flag should be selected if this is the final pickup for the entity.

Final Farm Pickup – this flag should be selected if this is the final pickup for the farm.

Record Change – should be selected when records are modified after the initial projection.

User Override – this flag should be selected if true records will not be deleted when running projections.

Record Type – identifies the type of record.

Thinned Counter – displays the number of times the entity has been thinned. This field can be edited if required.

Processing Density – indicates the desired lbs/ft2 or kgs/m2 to be processed.

Target Head Count Steps – identifies the method in which the birds are selected.

Pickup Counter – identifies the number of pickups for the entity.

Date Feeders Off – displays the date the feeders were turned off, and can be edited if required.

Date Feeders Raised – displays the date the feeders were raised, and can be edited if required.

Catch Crew – identifies the crew catching the birds is LHS is being used.

Catch Date Time – displays the date and time the birds are to be caught.

User Catch Date Time – an optional field that informs the optimizer component that Short Range Projected Schedules line must be caught at a certain time (Start).

Unit Price – displays the per unit price of the birds sold.

Memo – system generated note field that recaps the statistics and selection process for the entity.

Error Reason – identifies the reason for error in selecting the entity.

Notes – a field to enter further information regarding the entity selection. The Notes field also displays how the weight is calculated. The calculation can be viewed in Weight Calculation.

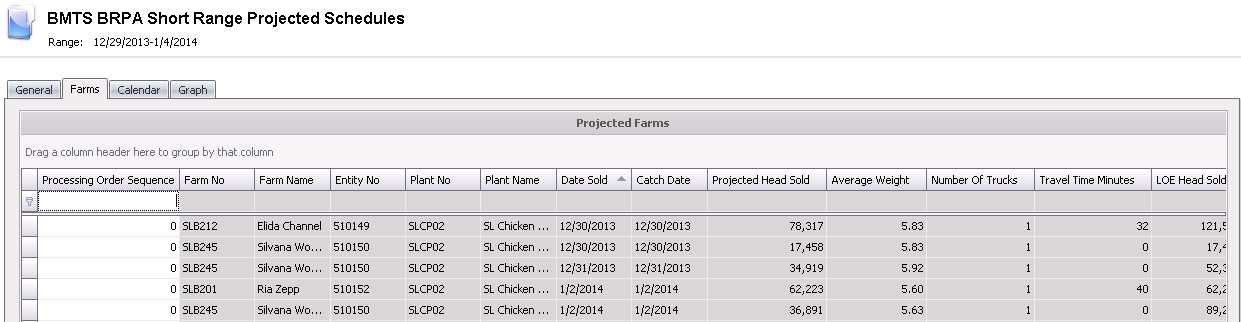

The Farms tab is a view of the short range by Entity with added LOE information. No editing is allowed on this screen except for the Processing Sequence.

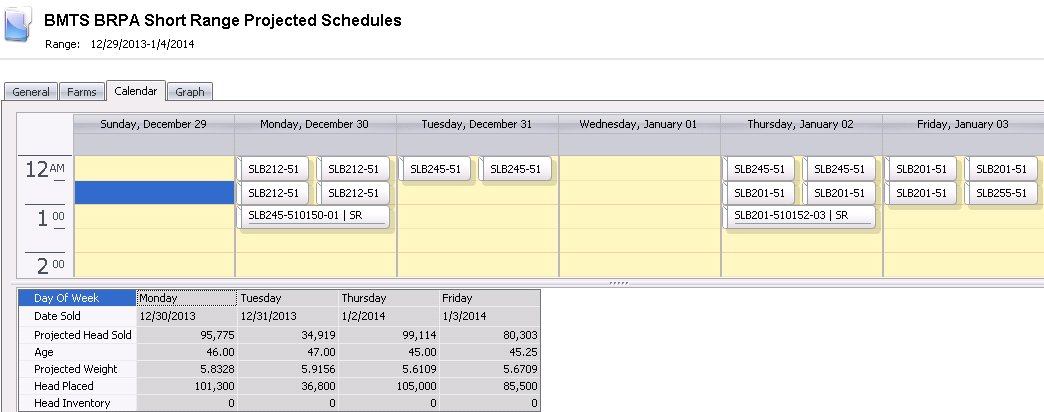

The Calendar view displays the short range in a calendar format. Entities can be moved by using the drag and drop option. There are options to view the calendar in daily, weekly or monthly views.

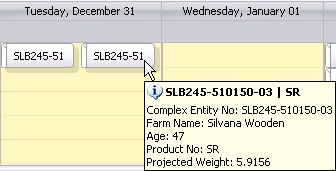

By Hovering over an Item, the basic information can be viewed in a bubble.

Items can also be relocated by dragging and dropping the item to a new day or time.

By right-clicking on the item and selecting 'Copy', the item can be duplicated by using the 'Recurrence' option. *Note: The new records will be the same as the record used to create the occurrences; the only difference will be the dates.

Once the projection has been run, the projection logs can be viewed. The logs are displayed for the profile of the record that the user has selected.

Click on any projection line for the required profile.

Right-click and select Projection Logs.

Select on of the following logs:

Last Projection - displays all the records created when the last projection was calculated.

Initial Entity Queue - displays the entities that were in the list to be projected including the projected weight based on the date of the selected record. The log will also display the current inventory and the projected inventory based on the future projections that exist.

Last Projection Summary - indicates the target which the projection was run and all of the projected entities linked to the target. The variance between actual projected and target head will be calculated.

Last Projection Farm Summary - displays the summary of the last projection by farm.

Last Projection Summary (Multi-Product) - displays each target grouped by date and product group or product. The log will indicate all of the entities that were projected for that date and product group or product along with the variances between actual and target.

The Long Range Forecast is based on future placements. The Long Range Forecast will predict future placements based on target kill volumes. Once the planned kill schedule has been calculated, the user may modify the data as required.

The following processes are outlined in this section of the document:

Before Long Range can be calculated, a base or starting point for the Long Range must be created. This can be done by a manual entry or by using the import feature. These methods are only done the first time a Long Range is created.

to create

a new record.

to create

a new record.

1. In BMTS>BRPA>Projections , select Long Range.

2. In the Long Range main index, click to create a new record.

3. In the Profiles dialog box, select the profile from the Profile No drop-down menu and then click 'OK'.

4. In the Long Range Projected Schedules screen, click the drop-down menu to add a new line and select from one of the following options: `Default` or `Breeder`. Selecting Breeder will allow the user to enter each individual field. Select Default to view the Projected Entity List.

5. From the entity list, select the row to highlight the entity or select multiple entities by holding the Ctrl key down while selecting the entities.

6. Click 'OK' and entities will be moved to the Projected Schedule screen.

7. Save and close the record. The record will be moved to the Short Range main screen.

The Calculations section is comprised of the following two components:

The following is the calculation for the Projected Average Weight. The details for the calculation in the Short Range Projection can be viewed in the Notes field.

| Parameter | Location/Comment | Value |

| Age | Difference between Placement Date and Processing Date | 48 |

| Weight Factor | BRPA Products>Performance - weight for age of entity | 5.8582 |

| Farm Factor | BRIM>Farms>BRPA>Weight Perf Factor | 1.0153 |

| Breed Factor | BRPA Products>Breed Factors>Weight | 1.0000 |

| Parent Age Breed Factor | BRPA Products>Breed Factors>Parent Age | 0.9900 |

| Seasonal Factor | BRPA Products>Seasonal Factors>Weight (month sold) | 1.0200 |

| Projected Weight | Calculation of all weight fields** | 6.0061 |

** Projected Weight = 5.8582 x 1.0153 x 1.0000 x 0.9900 x 1.0200 = 6.0061