Plants

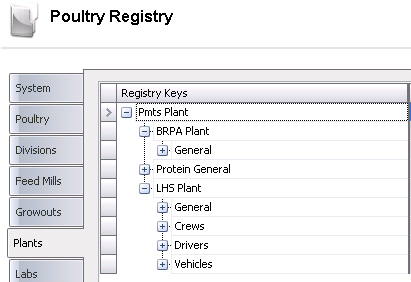

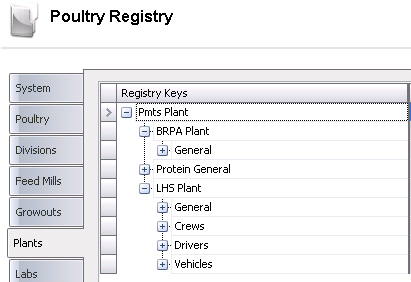

The Plants tab contains the configuration for plants, BRPA and LHS.

- In Admin>System>Registry,

click Poultry Registry.

- Select the Plants

tab and then click the Pmts Plant child grid

to open it up.

to open it up.

BRPA Plant

The BRPA Plant section contains all registry settings related to BRPA

to create processing schedules.

Actual Weight

Days is the number of days prior to harvest to look for BRIM

field weight transactions or to process the receiving transaction

- If the Allow

Mix Flock Placements flag is selected, the program will create

products with mixed flocks when necessary.

- BRPA Mode

is used to select the model for BRPA Planning schedules. Available

options are: FIFO (First-In First-Out), First Pickup Thin with Lock,

Thinning or Thinning with Lock.

- Catch Time

is the start time used to update the catch date time when a new record

is created.

- Feed Consumption

Mode is used to project weight using feed consumption by farm

or house up to the last inventory date. Weight is projected based

on previous week feed conversion and the total feed consumed for the

entity. If Feed Consumption is not used, select Off to improve performance

when projecting weight.

- Feed Factor Error

Threshold is the allowable variance (plus or minus) of projected

weight adjusted by feed consumption to be marked as outside range

when projecting weights.

- Head Capacity

Mode determines the capacity mode for BRPA projected placements.

Available options are:

- House Capacity

- BRPA will utilize capacity when created projected placements.

- Density

- projected placements will utilize the house area and month density

(area/density) to determine head place.

- Hours Prior To

Catch Time (Raise Feeders) is the default time prior to kill

time to turn feed off.

- Hours Prior To

Catch Time (Feeders Off) is the default time prior to kill

time to turn feeders off.

- When the Include

Factors flag is selected and the weight mode is percent deviation,

the logic will include the weight factor, farm factor, seasonal factor,

breed factor and parent age breed factor when calculating the projected

weight. If the flag is not selected, only the weight factor will be

used to calculate the projected weight.

- Minimum Cleanout

Days is used to enter the minimum days to clean out a house.

- Out Of Target

Priority has two available options:

- Next Available

- will select the flock to be harvested if it exceeds the weight

or max product age but select it at the next available target.

- Exceed Target

- will select the flock to be harvested if it exceeds the weight

or max product age even if it is going to exceed the target head.

- Parent Age Break

1-4 fields are used to group breeder parent flock ages at the

time of egg set, into age ranges. The BRPA Performance Profile will

analyze broiler flock performance based on this. Parent Age Break

1 will include all broiler flocks who parent flock age was capitalized

up to a selected value; Parent Age Break 2 will include all flocks

whose parents were greater than Age Break 1 up to a selected value.

- If the Post Placements

Create Chick Transactions flag is selected, Post will automatically

create a chick transaction for every placement entered.

- If the Post Movement

Create Transfer flag is selected, Post will automatically create

a transfer for every placement with a source entity entered.

- Projected Weight

Calculation Mode is the calculation mode for projected weights.

Available options are:

- Farm or

House - the BRPA performance factor will look at the house

and if it is not defined there, it will look at the farm; if the

farm does not have a value, `1` will be used.

- Farm and

House - the BRPA performance factor will use the house

BRPA performance factor and farm BRPA performance factor; f they

do not have a value, `1` will be used.

- Split House Threshold

specifies the minimum head inventory for a single house for which

BRPA can schedule a split pickup for the house. Any house with less

birds than this threshold will be scheduled as a single pickup for

the entire house.

- If the Time Precision

flag is selected, projected weights will calculate to a fraction of

a day based on harvest time.

- If the Truck

Capacity Rounding flag is selected when the head count of a

pen exceeds the truck capacity, it will add another truck to pickup

the remaining head. If the flag is not selected, the head count will

be added to another pen in the house.

- If the Use Fixed

Cycles flag is selected, BRPA will use the specified parameters

in the BRIM House master to create brood placements and grow movements

when generating projections.

- If the Validate

Processing Health Status flag is selected, BRPA logic will

schedule the entities based on the processing control status. If Processing

Control Status is set to End of Day and the entity has at least one

positive result at the time that the projection is run, the entity

will be scheduled to be processed at the end of the processing day.

If Processing Control Status is set to End of Week and the entity

has at least one positive result at the time that the projection is

run, the entity will be scheduled to be processed at the end of the

last processing day of the week. LHS will schedule the pick up at

the end of the day that the entity is scheduled to be processed.

- Weight Factor

Error Threshold is the allowable variance (plus or minus) of

projected weight adjusted by test weight to be marked as outside range

when projecting weights.

- Weight Mode

determines the weight mode for weight calculations related to kill.

Available options are:

- % Deviation

- the program calculates the bird weight using all factors for

the same age as the actual weight is captured, then it calculates

the % deviation from the actual and applies the same deviation

to the kill age projection.

- Weight Gain

- weight gain per day is re-calculated based on the actual weight

captured, and then the new weight gain per day is used moving

forward to create the kill age projection.

- Weight Mode Priority

determines the priority for weight mode. Available options are:

- Field Transactions

Only - will only utilize a field transaction.

- Processing

Transactions and Field Transactions - will always utilize

the most current transaction date closest to Harvest date.

- Processing

Transactions Only - will only utilize a processing transaction.

- Processing

Transactions then Field Transactions - will utilize a processing

transaction and then a field transaction if there is no processing

transaction.

- None

- will bypass the logic and no weight will be used.

- Weight Projection

Mode determines the mode for weight projections.

- Date Sold

- the standard weight and total weight gain to harvest will be

calculated up to the date sold age.

- Date Sold

Minus One - the standard weight and total weight gain to

harvest will be calculated up to the date sold age minus one.

Protein General

If the Processing

Auto Reference No flag is selected, the program will generate

the next sequential number. Reference number field will be read-only.

- If the Zero Weight

Required flag is selected, the program will enter Farm Gross

Zero Weight before entering Farm gross Weight, along with Plant Tare

Zero Weight before Plant Tare Weight.

LHS Plant

The LHS Plant section defines the parameters that will be used in LHS

for projecting live haul loads.

General

Transportation

Model refers to the driver/crew team area. Drivers and crews

stay together as teams work in certain designated areas. Available

options are:

- Single Unit

Truck - used when no trailers are defined. The truck stays

with the birds right through until the end processing time.

- Single Unit

Truck Driver `til Processing - used when trucks and trailers

are defined. The truck and trailer stay together until the end

processing time.

- Single Unit

Truck Driver `til Unload - used when trucks and trailers

are defined. The truck and trailer stay together until the end

unload time.

- Trailer

Drop And Hook - used when trucks and trailers are defined.

Trailers are unhooked when taken to the farm and unhooked later,

possibly by another truck and driver.

- Unhook At

Plant - used when trucks and trailers are defined. The

truck stays with the trailer at the farm but unhooks when brought

back to the plant at the end unload time. The truck then takes

a different trailer if one is available.

- Unhook At

Plant and Hook an Available Trailer - used when trucks

and trailers are defined. The truck stays with the trailer at

the farm but unhooks when brought back to the plant at the end

yard time. The truck then takes a different trailer if one is

available.

- Default Travel

Time is used for Crew To Farm, Plant To Farm, and Farm To Farm.

Travel time is calculated using the Travel Time defined within the

Farm master. If no travel time is defined, then the distance within

the farm master is multiplied by Average Truck Speed. If not distance

is entered, then Default Travel Time is utilized.

- The Calculate

Plant/Line Speeds Based on Head flag will adjust the line speed

based on the had to be processed during the day to meet the plant

hours work time.

- Balance Crafts

in a Load will balance the number of birds in the crate for

each load; it will adjust the number of birds and crates per truck.

Available options are:

- Balanced

- based on the number of loads projected, the birds in the crate

will be balanced following the Min and Max parameters defined.

- Max Capacity

- the crate will be filled with the maximum capacity of birds

specified on each line.

- Max Travel Time

Reduction Percent will reduce the travel time by the percent

specified only if it is necessary to be on time to pick up the next

load.

- Processing Transactions

Post Mode determines how processing transactions will be created,

based on Planned Live Haul or Projected Schedules.

- Pickup House

Priority indicates the order in which houses/pens from a single

farm will be uplifted. This order is applied after the plant line

product order.

- Max Truck Weight

Capacity Mode will load the truck based on the maximum number

of crates defined or its maximum weight capacity.

- Max Threads

is the maximum number of threads used by the optimizer.

- Time Interval

is the length of the time period display. All times will be rounded

to the nearest `Tim Interval`.

- Initial

Travel Time specifies what value will be used to calculate

the travel time on the first load of the day. Available options are

Plant to Farm or Resource Travel Time.

Crews

Calculate

Crates Mode is used to set how the calculation of crates is

performed.

- Crew Starting

Hours Mode working hours for a crew will begin from their last

catch time until their last load finish time, or from the time they

start to drive to the farm until the time they arrive back at their

starting location.

- Multiple Crews

Per House Mode determines how the crews are scheduled in the

hosues. Available options are:

- Multiple

Crews - schedule a crew to begin a house and end their

shift before finishing a house, and then schedule another crew

to finish the house.

- One Crew

Per House - strictly schedule one crew per house.

- Simultaneous

Crews - schedule more than one crew per house.

- House Catching

Gap determines how a crew operates once it starts catching

a house. Available options are:

- Allowed

- allows a crew to start catching a new house to complement their

last load if their last load is a partial load

- Not Allowed

- one a house has begun to start catching, the catching cannot

stop until all birds from that house have been caught.

Drivers

Driver First

Load Preparation Time is the time, in minutes, for a

driver to prepare the truck for the first load of the day.

- Next Load Preparation

Time (Minutes) is the maximum number of minutes it will

take to prepare for the next load.

- Driver Switch

Truck Time is the number of minutes required for the

driver to prepare before driving a new truck.

- Max Driving Time

Without Break is the maximum number of hours a driver

can driver without taking a break.

- Driver Break

Time is the time designated for the driver`s break, in

minutes.

- Max Driver Wait

Time At Farm is the limit on how long a truck would wait

if it could arrive early. This field is only utilized when the Transportation

Model = Trailer Drop And Hook.

Vehicles

Average Truck

Speed is used with Travel Time. Travel time is defined

using the Travel Time defined within the Farm master. If no Travel

Time is defined, then the distance within the Farm master is utilized,

multiplied by `Average Truck Speed`.

- BIO Security

Cleaning Time is the number of minutes taken to clean

the vehicle before it leaves the farm. This time will be added after

the Catch End Time and before the Drive To Plant Start Time.

- Forklift Crate

Adjustment is the amount of crates that need to be removed

from the truck when taking the forklift back to the plant.

- Farm Trailer

Load Time is the time, in minutes, to hitch up the

trailer when the driver brings the truck to pick up a load at a farm.

This field is only utilized when using Transportation Model = Trailer

Drop And Hook.

- Unload Time (Minutes)

is the unloading time, in minutes, that a driver must wait before

taking the truck to the next farm

- Truck Down Time

Mode determines how the truck operates once it starts unloading

in the Plant. Available options are:

- Finish Current

Load First - once a truck has begun unloading the crates,

it cannot stop until all the crates have been downloaded.

- Stop Processing

Immediately - once a truck has begun unloading the crates

and there is a break time in the line, the truck has to wait until

the line starts again to continue the process.