order shipments

Order

Shipments are sourced from existing sales orders and remove the product

from inventory.

A Sales

Order must be created prior to creating an order shipment.

The following procedures are

outlined in the Order Shipment document:

Create

an Order Shipment

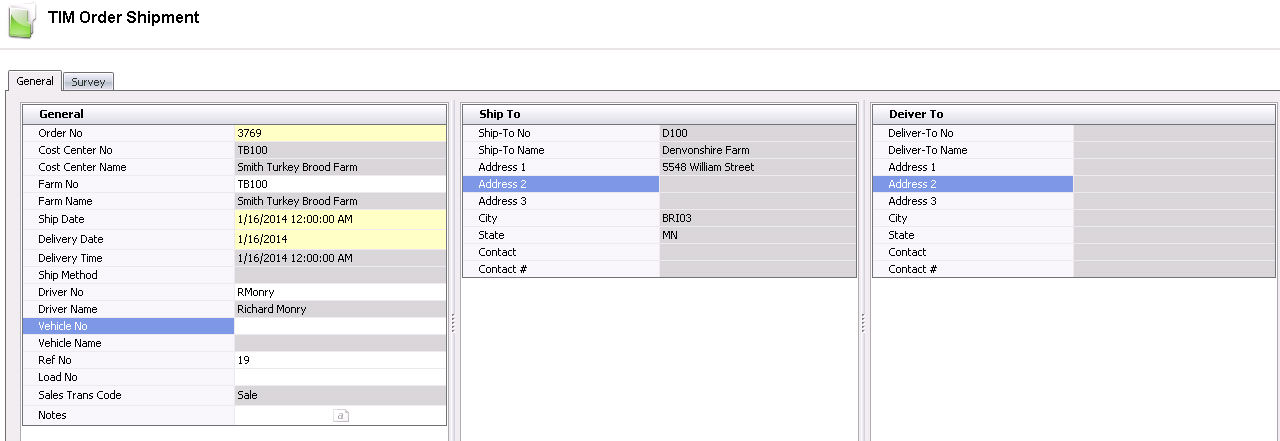

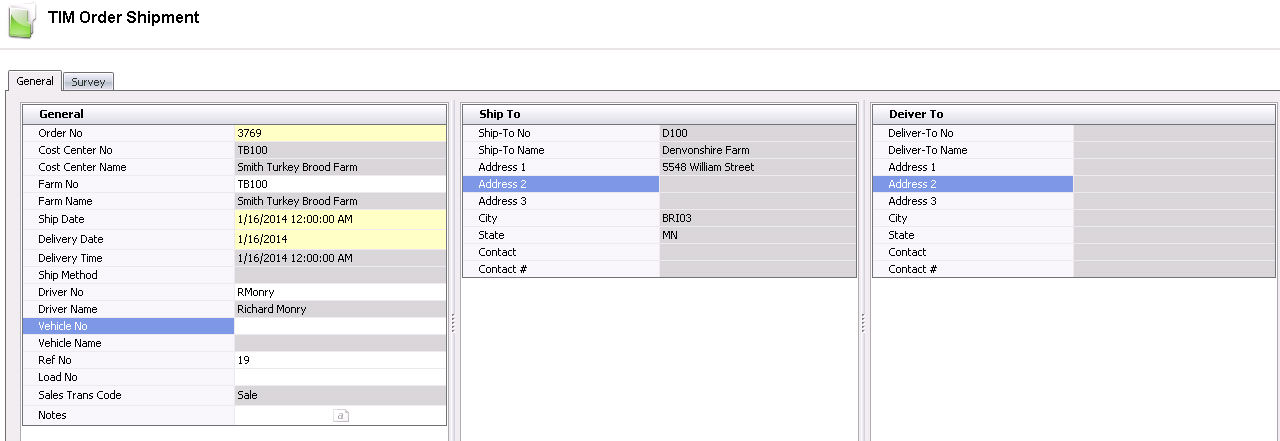

General

The General tab contains the following components:

Order

Shipment Header

The order shipment header

contains the base data to outline the shipment. The header is divided

into three sections to group the data. Most of the information defaults

in and is derived from the associated sales order.

- In

TMTS>BIM>Transactions,

select Order Shipments.

- In

the Order Shipment

main index, click the

button to create a new order shipment

button to create a new order shipment

- Click

on the General tab.

General

- From

the Order No drop-down

menu, select the sales order to be shipped. Order No is an auto-assigned

unique number that was assigned to the order when it was initially

created.

- Cost Center No will default

in and identifies the cost center from where the product will be shipped.

- Cost Center Name will default

in and displays the name of the cost center.

- From

Farm No, select the

farm from where the product will be shipped.

- Farm Name will default in

and displays the name of the farm.

- Enter

the Ship Date to

indicate the date that the product will be shipped.

- Enter

the Delivery Date to

indicate the date the product will be delivered.

- Delivery Time will default

in with no option to modify.

- Ship Method will default in

if applicable, with no option to modify.

Driver No is an optional field to

identify the driver who will be transferring the product. Drivers

must be set up prior in: Admin>Business>General>Definitions>Drivers.

- Driver Name

will default from Driver No and displays the name of the driver.

Vehicle

No is an optional field to identify the vehicle used to transfer

the product. Vehicles must be set up prior in: Admin>Business>General>Definitions>Vehicles.

Vehicle Name will default from Vehicle

No and displays the name of the vehicle.

Ref No is a unique reference number

that identifies the order shipment transaction. This can be manually

or automatically entered.

Load No is an optional field to

enter the load number of the shipment.

Sale Trans Code identifies the type

of transaction and will default to Sales.

In

the Notes field, enter any

additional information relating to the order shipment.

Ship

To

The Ship-To tab contains the

base data for the ship-to customer. The details in the tab will default

in from the sales order with no option to modify.

- Ship-To No displays the code

that is used to identify the ship-to customer.

- Ship-To Name displays the

name of the ship-to customer.

- Address 1-3 fields display

the address details of the ship-to customer.

- City displays the city in

which the selected ship-to customer is located.

- State displays the state in

which the selected customer is located.

- Contact defaults from the

primary contact defined on the Ship-To customer.

- Contact # defaults from the

Ship-To customer and displays the main contact telephone number, if

applicable.

Deliver

To

The Deliver-To tab contains

the base data for the deliver-to customer. This tab will be populated

if the deliver-to customer is set up in the Business Usages tab of Customers.

The details in the tab will default in from the sales order with no option

to modify.

- Deliver-To No displays the

code that is used to identify the deliver-to customer.

- Deliver-To Name displays the

name of the deliver-to customer.

- Address 1-3 fields will default

in and display the address details of the deliver-to customer.

- City displays the city in

which the selected deliver-to customer is located.

- State displays the state in

which the selected customer is located.

- Contact defaults from the

primary contact defined on the Deliver-To customer.

- Contact # defaults from the

Deliver-To customer and displays the main contact telephone number,

if applicable.

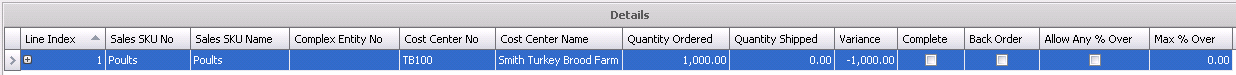

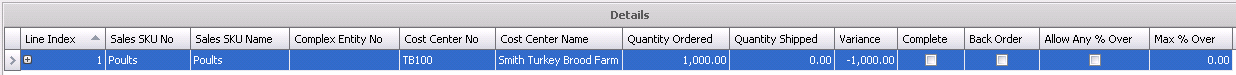

Order

Shipment Details

The Detail lines and fields

in the Details tab will default from the selected sales order.

- Line Index identifies the

line number of the order.

- Sales SKU No identifies the

product that is being shipped.

- Sales SKU Name displays a

description of the product being shipped.

- Complex Entity No displays

the entity number of the farm.

- Cost Center No indicates the

cost center where the product is being shipped from.

Cost Center Name defaults from Cost

Center No and displays the name of the cost center.

- Quantity Ordered displays

the number of units ordered that are requested to be shipped.

- Quantity Shipped displays

the quantity of units that were actually shipped. This field will

be populated when the product inventory is selected.

- Variance will be automatically

calculated and displays the difference in unit amounts between Quantity

Ordered and Quantity Shipped, if applicable.

- The

Complete flag is selected

if the order shipment is complete and shipping has been completed.

- If

the order was not completely shipped, but the remaining quantity will

be shipped on another shipment, select the Back

Order flag. For example, if 1000 units were ordered,

but only 750 are available to be shipped today, and the remaining

250 will ship tomorrow, then the back order flag should be selected.

On the other hand, if only 750 units are available to be shipped and

the remaining 250 units will never be shipped, the back order flag

should be left de-selected.

- Allow Any % Over

defaults as a read-only field from the product and lets the

user know if additional quantities from the order quantity can be

shipped. If this flag is selected, there

is no limit on the product amount and the customer can be shipped

any quantity over the specified product units.

- Max % Over defaults

as a read-only field from the product and is

used when the product has a tolerance percentage for the order shipment.

(Example: The order shipment has 100 units. Max % Over is defined

as 5%, which means the receiving transaction will allow up to an including

5 additional units).

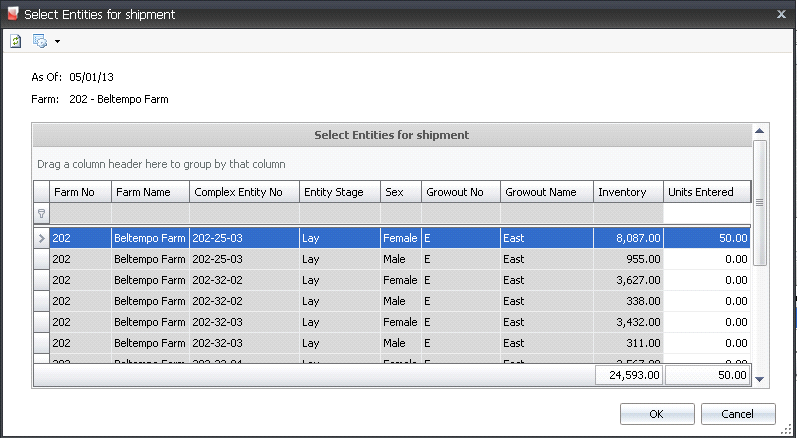

Additional

Details

Within the Details tab, there

is a child grid to add additional details relating to the order shipment.

The child grid section is

comprised of three tabs:

- Click

on the Line Index tab to display the child grid.

on the Line Index tab to display the child grid.

- Click

to add a new item line.

to add a new item line.

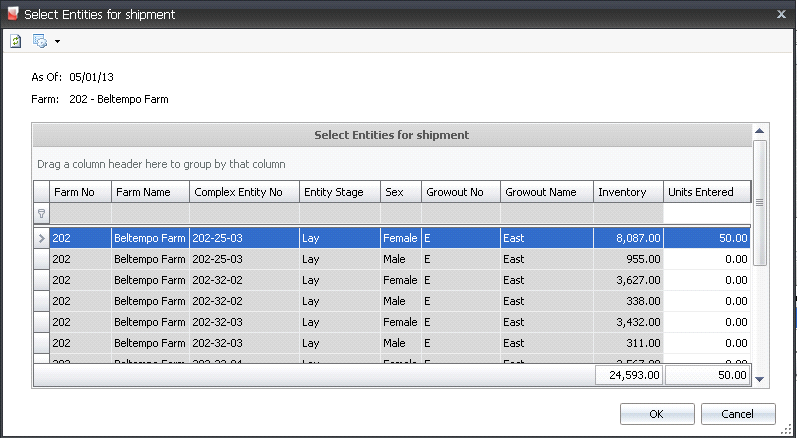

- The

Select Entities for Shipment dialog box will appear with all available

entities.

- Select

the required Complex Entity No and in the Units

Entered field, enter the number of units to be shipped.

- Click 'OK'.

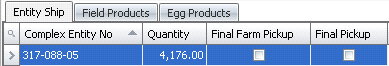

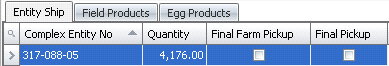

- Complex Entity No displays

the entity where the product is shipped from.

- Quantity displays the number

of units shipped.

- Select

the Final Farm Pickup

flag if the final pick-up from the farm has been completed.

- Select

the Final Pickup flag

if this is the last pick-up of the product at the farm.

Field

products can be added when selling a field product, such as medication,

vaccination, or miscellaneous supplies.

- Click

to add a new line item.

to add a new line item.

- In

the pop-up dialog box, select the required field product and in the

Units Entered field,

enter the number of units to be shipped.

- Click

'OK'.

- Lot No is a unique identification

number for the field product, and is optional.

- Quantity displays the amount

of field product units that are being shipped.

- Product No displays the code

for the field product.

- Product Name defaults from

Product No and displays a description of the product.

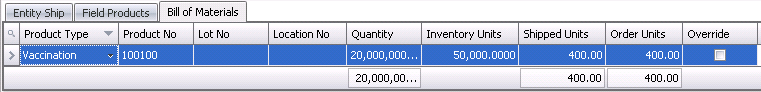

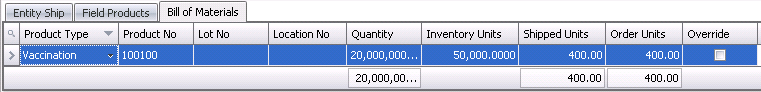

The fields in the Bill of

Materials tab will default in from the sales order.

- Product Type displays the

type of product ordered.

- Product No identifies the

product.

- Lot No indicates the lot number

of the product, if applicable.

- Location No identifies the

location of the product, if applicable.

- Quantity displays the total

amount.

- Inventory Units displays the

total number of units of the product.

- Shipped Units displays the

total number of shipped units.

- Order Units displays the total

number of units in the order.

- Select

the Override

flag to cancel the order.

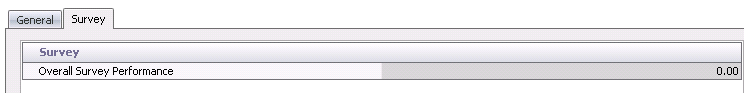

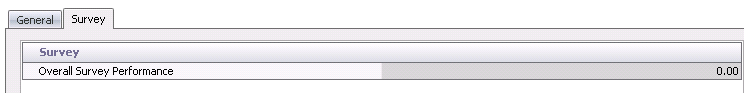

Survey

Survey Codes are set up in:

Admin>Business>General>Order

Management>Survey Codes The codes are then displayed on

the Order Shipment tab, where the user enters a value from 1 (lowest)

to 10 (highest). The system will calculate an average score for the shipment.

Post

an Order Shipment

Once the order shipment has

been created and saved, the shipment needs to be posted. The posting process

locks the order shipment to prevent edits, and creates the journal transaction

to record the receivable and revenue accrual. If internal pricing is used,

the credit to inventory and debit to cost of sales will be recorded using

the internal price and adjusted to actual at period end. The UnPost option

unlocks the order shipment transaction and reverses the journal transactions.

- In the

Order Shipments main index, select the required order shipment transaction

and right-click to select 'Post'. Alternatively, click the green check

mark

in the top menu bar and select 'Post Record(s).

in the top menu bar and select 'Post Record(s).

- To un-post

an order shipment, select the required order shipment and right-click

to select 'UnPost'. This process will set the transaction status

to 'Reversed' status, which allows the transaction to be edited.

Journal

Transaction

The posting process creates

the journal transaction. The journal will accrue the sales revenue and

accounts receivable based on the values that are defined in the sales

order. The posting process will also credit the inventory for the cost

of the product and debit the cost of sales based on the internal price

defined. The period end process

reverses the internal price and records the actual cost of the product.

button to create a new order shipment

button to create a new order shipment

on the Line Index tab to display the child grid.

on the Line Index tab to display the child grid. to add a new item line.

to add a new item line.

to add a new line item.

to add a new line item.

in the top menu bar and select 'Post Record(s).

in the top menu bar and select 'Post Record(s).