processing

Processing transactions are completed in separate

transactions depending on the type of transaction.

- Internal

– Transfers from the farm to an internal plant at cost. Cost will

be determined in the period end process.

- Sales

– Sold from farm to an external plant. Revenue is based on the order

price at time of sale with the cost of sales being determined in the

period end process. There is a switch in setup to determine if customers

are charged on a per head or weight basis.

- Intercompany

Sales - The farm is a profit center and sells the animals to

an internal plant.

The Entity must be created

before creating a Processing transaction.

The following procedures are outlined in the Processing transaction

document:

Create

a Processing Transaction

There are several tabs in the processing transaction to record the statistical

processing data for the entity.

- In SMTS>SIM>Movements,

select Processing.

- In the Processing

Transactions main index, click

to create

a new processing transaction.

to create

a new processing transaction.

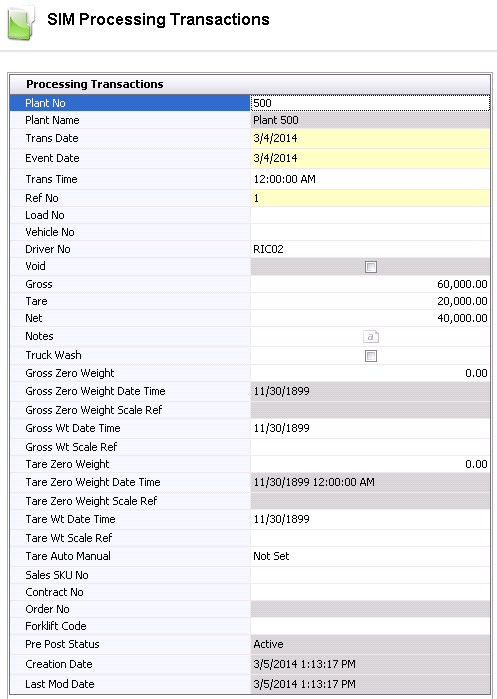

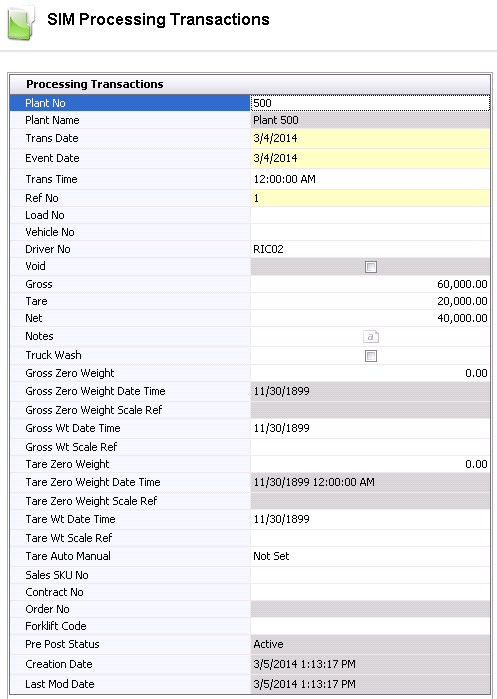

Processing

Transactions

- Click on the Processing Transactions tab.

- From the Plant

No drop-down menu, select the plant that is being processed

for the transaction.

- Plant Name

will default in from Plant No.

Trans Date

displays the date of the processing transaction.

Event Date

defaults to the trans date. The date may be changed if the transaction

actually occurred on a different date, however this date does not

affect inventory or accounting.

In the Trans

Time field, enter the time of the transaction.

Ref No

is an automatically generated field and displays a unique reference

number for the transaction.

Load No

indicates the load number of the delivery.

Vehicle No

is an optional field to identify the vehicle used to transfer the

product from farm to plant. Vehicles must be set up prior in: Admin>Business>General>Definitions>Vehicles.

Driver No

is an optional field to identify the driver that transfers the product

from farm to plant. Drivers must be set up prior in: Admin>Business>General>Definitions>Drivers.

Selecting the Void

flag will cancel the transaction and exclude it from farm and entity

data.

In the Gross

field, enter the gross weight of the loaded truck.

- In the Tare

field, enter the weight of the truck after it has been unloaded.

- In the Net

field enter the weight of the truck delivered to the plant.

- In the Notes

field, enter any additional information relating to the processing

transaction.

- Select the Truck

Wash flag if the truck was washed at the plant.

- In the Gross

Zero Weight field, enter the gross zero weight at the

plant.

- Gross Zero Weight

Date Time displays the date and time that the gross zero weight

was recorded at the scale.

- Gross Weight

Scale Ref displays the reference number for the gross zero

weight scale reading.

- Gross Wt Date

Time displays the date and the time that the gross weight was

recorded at the scale.

- Gross Wt Scale

Ref displays the reference number for the gross weight scale

reading.

- In the Tare Zero

Weight field, enter the tare zero weight at the plant.

- Tare Zero Weight

Date Time displays the date and time that the tare zero weight

was recorded at the scale.

- Tare Zero Weight

Scale Ref displays the reference number for the tare zero weight

scale reading.

- Tare Wt Date

Time displays the date and time that the tare weight was recorded

at the scale.

- Tare Wt Scale

Ref displays the reference number for the tare weight scale

reading.

- Tare Auto Manual

indicates the tare setting of Auto or Manual.

- If the customer is assigned to a pricing contract,

from Contract No, select the

contract that applies to the processing transaction.

- Order No

is used if the processing transaction is to an external plant where

hogs are sold to the plant. When the processing transaction is created,

the Order No field will populate with the sales order number that

is created.

From Forklift

Code, select the forklift that is used for the processing transaction.

Forklifts must be set up prior to use in: Admin>Business>General>Definitions>Forklifts.

Pre-Post Status

will default in and indicates if the transaction is Active or Posted.

Creation Date

indicates the date the transaction was created.

Last Mod Date

indicates the date the transaction was last modified.

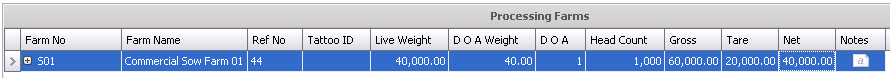

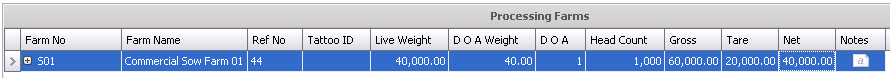

Processing Farms

The Processing Farms section contains the processing data for the farms

that were processed in the transaction.

- Select the Processing Farms tab and click

to

add a new farm detail line.

to

add a new farm detail line.

- From Farm No,

select the farm where the hogs are being transferred from.

- Farm Name

will default in.

- In the Ref No

field, enter a unique reference number for the processing transaction

line.

- Tattoo ID

indicates the tattoo ID for the farm where the animals are sourced.

- In the Live Weight

field, enter the weight of the animals to be processed net of DOA.

This can be entered in lbs or kgs.

- In the DOA Weight

field, enter the weight of the animals that arrived dead on arrival

to the plant.

- In the DOA

field, enter the number of head dead on arrival at the plant.

- In the Head Count

field, enter the number of head that are to be processed.

- In the Gross

field, enter the gross weight of the total head received. This can

be entered in lbs or kgs.

- In the Tare

field, enter the tare weight of the vehicle transporting the animals.

This can be entered in lbs or kgs.

In

the Net field, enter the net

weight of the total head received, including DOA. This can be entered

in lbs or kgs.

In

the Notes field, enter any

additional information related to the farm.

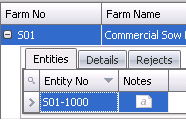

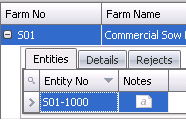

Additional Details

The Additional Details section is where the user enters the details

related to the processing transaction. The section contains three tabs:

Entities

- Select

the child grid on the Farm No field.

- Select the Entities tab and click

to add a new entity line.

to add a new entity line.

- From the Entity

No drop-down menu, select the entity for the processing line.

The total number of entities

must equal the total in the processing line.

- Enter

any Notes related to the entity.

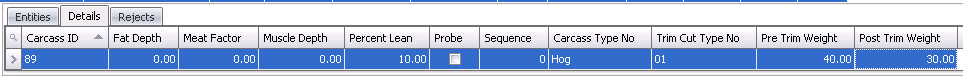

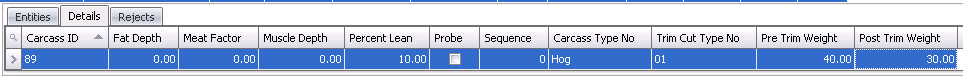

Details

The Details section is used to enter specific information for each animal/carcass.

- Select the Details tab and click

to add a new detail line.

to add a new detail line.

- In the

Carcass ID field, enter a

unique identification that is placed on the carcass for reference.

- Enter the Fat

Depth measurements of the carcass.

- Enter the Meat

Factor measurement.

- Enter the Muscle

Depth measurements.

- Percent Lean

is used to indicate the percentage of lean meat.

- Select

the Probe flag if a metal

probe was used to obtain the fat percentage.

- Sequence

is a numerical field to indicate the order in which the carcass was

processed.

- From Carcass

Type No, select from a list of user-defined carcass types.

Carcass types must be created prior to use in: Admin>Business>SMTS>Definitions>Carcass

Types.

- From Trim Cut

Type No, select from a list of user-defined trim cut types.

Trim cut types must be created prior to use in: Admin>Business>SMTS>Definitions>Trim

Cut Types.

- In the Pre Trim

Weight field, enter the weight of the carcass before trimming,

in either lbs or kgs.

- In the Post Trim

Weight field, enter the weight of the carcass after trimming,

in lbs or kgs.

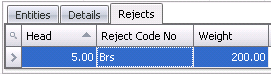

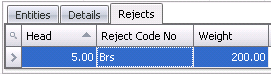

Rejects

The Rejects section is used to enter information related to the rejection

of the hogs.

- Select the Rejects tab and click

to

add a new reject line.

to

add a new reject line.

- In the Head

field, enter the number of hogs that were rejected.

- From Reject Code

No, enter the reason for the rejection. Rejection codes must

be set up prior to use in: Admin>Business>SMTS>Definitions>Processing

Reject Codes.

- Enter the total Weight

of the hogs being rejected.

Post

a Processing Transaction

Once the processing transaction has been saved and closed, it will need

to be posted. The posting process will lock the transaction from further

edits and post the statistics to the entity. As well, if the processing

transaction is to an external plant, the posting process will automatically

create the sales order and order shipment. For external processing, a

journal transaction will be created to debit the accrued receivable and

credit sales revenue as well as the cost of sales and inventory, only

if an internal price is established.

Journal entries will not be created for internal processing transactions

unless there is an internal price assigned to the product. If that is

the case, there will be a journal transaction created at post where it

will credit the flock value and debit the plant inventory for the internal

prices established for the product. There is a switch in setup to determine

if the product is priced based on a $/head or a $/lb or kg.

- In the Processing Transactions main index, select

the required transaction, rick-click and select 'Post.' Alternatively,

click the green check mark

in the top menu bar and select 'Post'.

in the top menu bar and select 'Post'.

- To un-post a processing transaction, select the

required transaction and right-click to select 'Unpost'. This

process will set the transaction status to 'Reversed' status, which

allows the transaction to be edited.

to create

a new processing transaction.

to create

a new processing transaction.

to

add a new farm detail line.

to

add a new farm detail line.

to add a new entity line.

to add a new entity line.

to add a new detail line.

to add a new detail line.

to

add a new reject line.

to

add a new reject line. in the top menu bar and select 'Post'.

in the top menu bar and select 'Post'.