Physical Inventory

Egg Room Physical Inventory is the process of taking a physical inventory

count. At the end of the fiscal period, most companies take an inventory

count. The difference between the perpetual or expected inventory and

the actual inventory is journalized to an inventory shrink account. The

Physical Inventory transaction records the difference between the perpetual

and physical inventory. The transaction will remove the eggs from inventory.

There are three options available to enter inventory counts.

- Physical

Inventory Count - When using this method, the user will enter

each line for the products that were counted.

- Auto-Load

from Inventory - This method will load all products in inventory

with the available inventory. The user will then enter the actual

inventory for the required products.

- Zero-Out

Inventory - The Zero-Out Inventory sets the quantity to zero.

When the record is saved, it will set all of the inventory records

to zero and create the adjustment, or the user can enter the inventory

quantities.

A Farm Receiving transaction must

be created before creating a Physical Inventory transaction.

The following options are outlined in this document.

Physical

Inventory Count

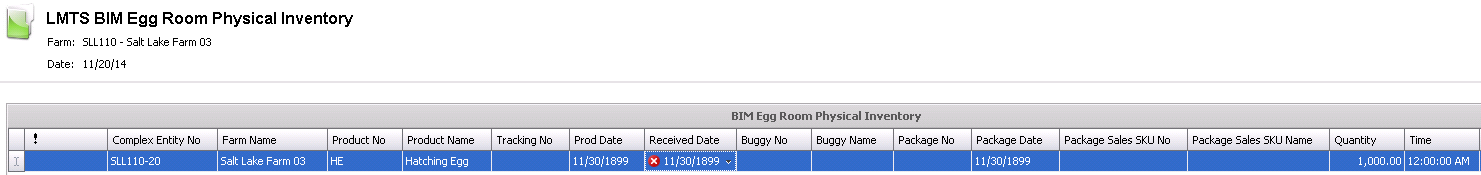

- In LMTS>BIM>Transactions>Egg

Room, select Physical

Inventory.

- In the Egg Room

Physical Inventory main index, click

to create a new physical inventory record.

to create a new physical inventory record.

- In the New Record dialog box, from

Farm No, select the entity/farm

where the inventory is located.

- Enter the Date

of the Physical Inventory and then click 'OK'.

- In the Physical Inventory screen, click

to add a new inventory product.

This will allow one product to be added at a time.

to add a new inventory product.

This will allow one product to be added at a time.

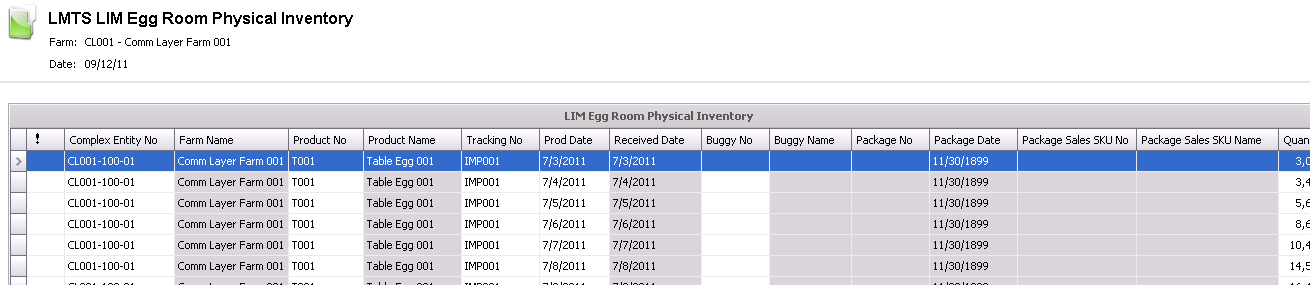

- From the Complex

Entity No drop-down menu, select the entity number of the farm

for the physical inventory.

- Farm Name

defaults in and displays the name of the farm where the physical inventory

is taking place.

- From Product

No, select the required product for the inventory count.

- Product Name

defaults from Product No and displays a description of the product.

- Tracking No

is a unique identification code use to identify the physical

inventory transaction. This can be manually or automatically entered.

- Prod Date

indicates the date the product was produced. This date can be modified

if required.

- Received Date

indicates the date the eggs were received at the hatchery.

- From Buggy

No, select the buggy that the product was packaged

from, if applicable.

- Buggy Name

displays the name of the buggy.

- Package No

displays a unique reference number used to identify the packaging

transaction, if the product was packaged.

- Package Date

displays the date the product was packaged, if applicable.

- Package Sales

SKU No indicates the sales SKU number of the package, if applicable.

- Package Sales

SKU Name displays the name of the package sales SKU, if applicable.

- In the Quantity

field, enter the total number of units of the selected product.

- Time indicates

the time of the production date and can be modified if required.

- Adjustment Quantity

calculates the difference between what he system says is there and

the amount that is actually counted. *NOTE: Adjustment

Quantity and Adjustment Value will be calculated once the physical

inventory transaction is saved.

- Adjustment Value

automatically calculates the value using the selected valuation methodology

of Average Cost or FIFO

- Book Quantity

displays the product quantity in units depending on the system's numbers.

When the record is saved, Book Quantity will update to reflect the

number entered in the Quantity filed.

- In the Comments

field, enter any additional information related to the inventory feed

product.

- The Consignment

flag will be selected if the product was purchased with a Consignment

Purchase Order.

- Selecting the Void

flag will cancel the transaction.

- Creation Date

indicates the date the transaction was created.

- Last Mod Date

indicates the date the transaction was last modified.

- Once the fields have all been entered, click

to save the inventory record, and then close the screen. Saving the

record will calculate the adjustment quantity and value. Ending Inventory

can be viewed in: Products>Inventory

from the folder.

to save the inventory record, and then close the screen. Saving the

record will calculate the adjustment quantity and value. Ending Inventory

can be viewed in: Products>Inventory

from the folder.

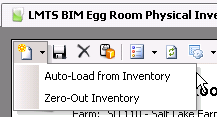

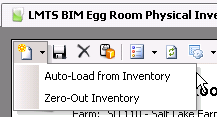

Auto-Load

from Inventory

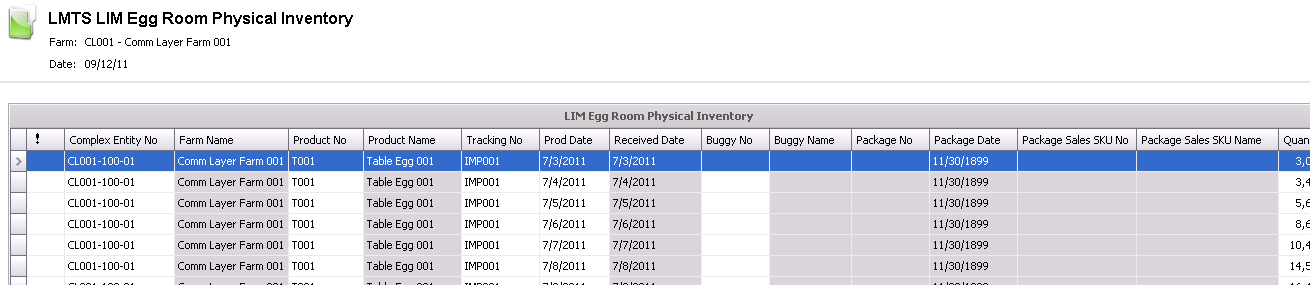

Alternatively, all products from inventory can be automatically added

at one time rather than adding individual products one at a time.

- To add all products from inventory, in the Physical

Inventory screen, click the

drop-down

menu and select 'Auto-Load from Inventory.'

drop-down

menu and select 'Auto-Load from Inventory.'

All

of the products in inventory for the selected date will be listed

on the Physical Inventory screen with the current inventory quantities.

- In the Quantity

field, enter the number of units of the selected product.

- If applicable, enter any additional information

In the Comments field.

- Once the fields have all been entered, click

to save the inventory record, and then close the screen. This process

will establish an ending inventory, unit quantity, and value.

to save the inventory record, and then close the screen. This process

will establish an ending inventory, unit quantity, and value.

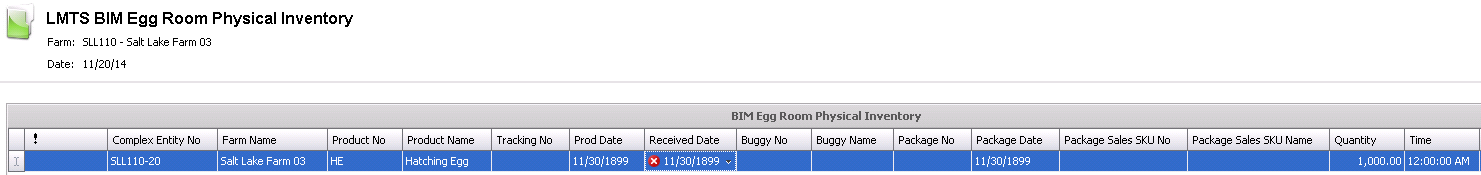

Zero-Out

Inventory

The Zero-Out Inventory sets the quantity to zero. When the record is

saved, it will set all of the inventory records to zero and create the

adjustment, or the user can enter the inventory quantities.

- To add products from Zero-Out Inventory, in the

Physical Inventory screen, click the

drop-down

menu and select 'Zero-Out Inventory.'

drop-down

menu and select 'Zero-Out Inventory.'

All of the products in inventory for the selected

date and farm will be listed on the Physical Inventory screen with

the inventory quantities set to '0'.

- In the Quantity

field, enter the number of units of the selected product.

- If applicable, enter any additional information

In the Comments field.

- Once the fields have all been entered, click

to save the inventory record, and then close the screen.

to save the inventory record, and then close the screen.

Post

a Physical Inventory Transaction

Once the physical inventory transaction has been created and saved,

the transaction needs to be posted. The posting process locks the transaction

to prevent edits, and updates the inventory based on the adjustment created.

- In the Physical Inventory main index, select the

required transaction and right-click to select 'Post'. Alternatively,

click the green check mark

in the top menu bar and select 'Post'.

in the top menu bar and select 'Post'.

- To un-post an egg room physical inventory transaction,

select the required transaction and right-click to select 'Unpost'.

This process will set the transaction status to 'Reversed' status,

which allows the transaction to be edited.

to create a new physical inventory record.

to create a new physical inventory record. to add a new inventory product.

This will allow one product to be added at a time.

to add a new inventory product.

This will allow one product to be added at a time.

to save the inventory record, and then close the screen. Saving the

record will calculate the adjustment quantity and value. Ending Inventory

can be viewed in: Products>Inventory

from the folder.

to save the inventory record, and then close the screen. Saving the

record will calculate the adjustment quantity and value. Ending Inventory

can be viewed in: Products>Inventory

from the folder.  drop-down

menu and select 'Auto-Load from Inventory.'

drop-down

menu and select 'Auto-Load from Inventory.'

to save the inventory record, and then close the screen. This process

will establish an ending inventory, unit quantity, and value.

to save the inventory record, and then close the screen. This process

will establish an ending inventory, unit quantity, and value. drop-down

menu and select 'Zero-Out Inventory.'

drop-down

menu and select 'Zero-Out Inventory.' to save the inventory record, and then close the screen.

to save the inventory record, and then close the screen. in the top menu bar and select 'Post'.

in the top menu bar and select 'Post'.