Rework transactions can be created based on the following transactions.

button to create a new Rework record.

button to create a new Rework record.

Enter the Feed Mill No creating the Rework.

Click `OK`. A new screen will appear.

Click on the  button to

create the transaction.

button to

create the transaction.

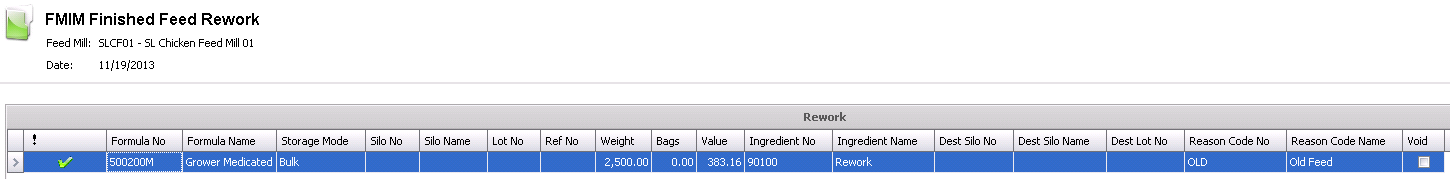

Select the Formula No from the drop-down menu to identify the feed formula that is being reclassified as rework.

Formula Name will populate based upon the Formula No selected and is a description of the Formula No.

Storage Mode will populate based upon the Formula No selected.

Select the Silo No if silo tracking is used. This represents the silo where the feed formula is located. The cost will be adjusted from that silo location.

Silo Name will populate when Silo No is selected and is a description of the Silo No.

Enter the Lot No if lot numbering is used. The field represents the lot number for the feed formula. The cost will be adjusted from that lot number.

Ref No is a field to enter or automatically generate a reference number for the transaction.

Enter the Weight of feed that is being reclassified as rework.

Enter the number of Bags that are being reclassified as rework.

Value is a calculated field that represents the estimated value of the rework transaction. The global post process will adjust the rework transaction to the actual cost for the period and record the difference to a variance account.

Ingredient No represents the rework ingredient. The ingredient will default based on the rework ingredient defined on the feed formula version but can be modified if required.

Ingredient Name will populate based upon the Ingredient No - is a description of the Ingredient No.

Dest Silo No is an optional field to enter the ingredient silo that the rework will be placed.

Dest Silo Name will populate based upon the Dest Silo No and is a description of the Dest Silo No.

Select the Reason Code No. This field is optional and explains the reason for the rework. Reason Codes must be pre-defined prior to use in: Admin>Business>FMTS>FMIM>Reason Codes.

Reason Code Name will populate based on the selected Reason Code No.

Selecting the Void flag cancels the transaction but leaves it in the system for audit purpose.