![]()

The system has the option to record physical inventory transactions for both ingredients and feed. There are two types of physical inventory transactions.

Regardless of the type of transaction, the user can load the existing perpetual quantities and enter the actual physical amounts. The system will calculate the difference in the perpetual and physical quantities.

The Physical Inventory document contains the following components:

to

create a new inventory record.

to

create a new inventory record.Non-Inventory: This transaction type is only used for internal reporting purposes to analyze inventory quantities. There is no valuation on this type of physical inventory transaction. Non-Inventory adjustments can be taken at any time in the period.

Adjustment: The adjustment transaction is used when the difference between perpetual and physical inventory is to be reported for financial purposes. Valuation is determined at global post and the difference is reported as a shrink variance. If the valuation method is FIFO, Adjustments can be entered at any time in the global post period. If the valuation method is Average Cost, the physical inventory adjustment must be recorded on the last day of the global post period.

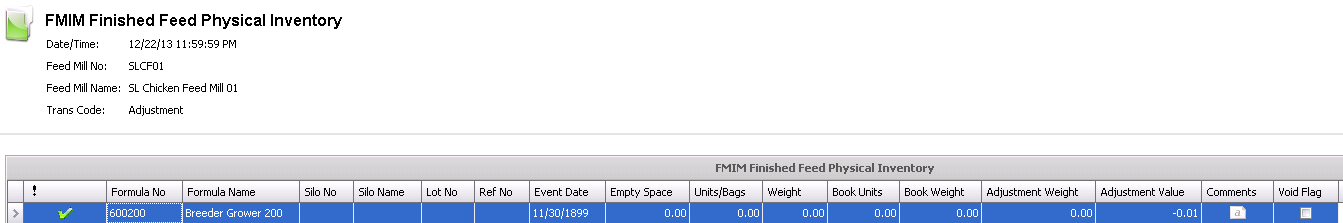

The Single Record option is used to enter one physical inventory line at a time.

Select to create a single record.

to create a single record.

Formula Name will default from Formula No and displays a description of the formula.

Lot No is an optional field used to record the lot number for the received ingredient.

Ref No is an optional field, and is the reference number for the physical inventory transaction.

Enter the Event Date of the transaction.

Enter the Empty Space of the silo and hit 'F12' while still in the field. This calculates the quantity based on the dimensions of the silo, the density of the ingredient, and the empty space. Empty Space is an optional field.

Units/Bags user enters the number of units in inventory. The quantity will default based on the book units/weight.

Weight is the calculated weight of the entered units based on the inventory units defined on the feed formula. Weight is calculated down to kgs or lbs.

Book Units perpetual inventory units based on the transactions that have been entered. Basically, what is expected to be in inventory.

Book Weight the calculated book weight of the entered units based on the inventory units defined on the feed formula. Weight is calculated down to kgs or lbs.

Adjustment Weight calculated difference between Weight (actual inventory) and Book Weight.

Adjustment Value estimated value of shrink adjustment. When global post is run, this will be updated to actual adjustment value.

In the Comments field, enter any additional details related to the transaction.

Click  to save the physical inventory record. The Book Units, Book Weight

and Adjustment will populate when the transaction is saved. An estimate

for the adjustment will be calculated. This value will be modified

when the physical inventory is valued during the global post process.

to save the physical inventory record. The Book Units, Book Weight

and Adjustment will populate when the transaction is saved. An estimate

for the adjustment will be calculated. This value will be modified

when the physical inventory is valued during the global post process.

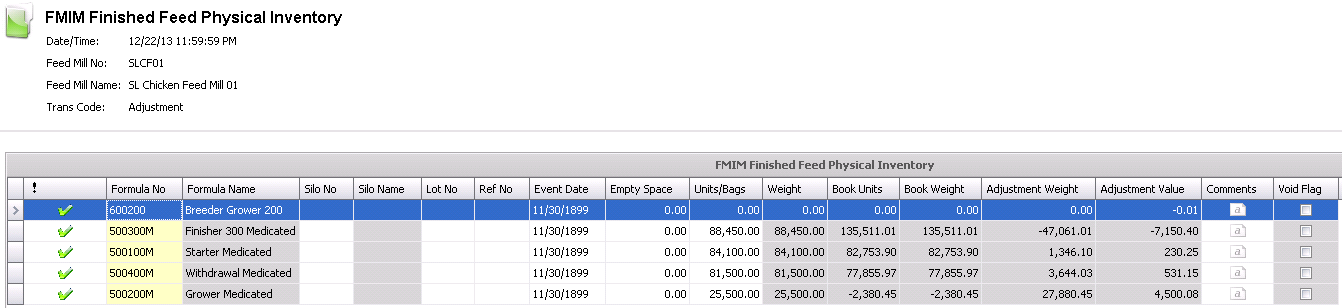

The Auto-Load feature will load the current inventory units based on the inventory that exists when the transaction is created.

Click

on the down arrow beside  and

select 'Auto-load From Inventory'. This will load all ingredients

in inventory with the current quantities.

and

select 'Auto-load From Inventory'. This will load all ingredients

in inventory with the current quantities.

Formula Name will default from Formula No and displays a description of the formula.

Lot No will be displayed for the formula if lot tracking is being used.

Ref No is an optional field, and is the reference number for the physical inventory transaction.

Enter the Event Date of the transaction

Enter the Empty Space of the silo and hit 'F12' while still in the field. This calculates the quantity based on the dimensions of the silo, the density of the ingredient, and the empty space. Empty Space is an optional field.

The Units/Bags will default based on the book units/weight in inventory. User can modify if required.

Weight is the calculated weight of the entered units based on the inventory units defined on the feed formula. Weight is calculated down to kgs or lbs.

Book Units perpetual inventory units based on the transactions that have been entered. Basically, what is expected to be in inventory.

Book Weight the calculated book weight of the entered units based on the inventory units defined on the feed formula. Weight is calculated down to kgs or lbs.

Adjustment Weight calculated difference between Weight (actual inventory) and Book Weight.

Adjustment Value estimated value of shrink adjustment. When global post is run, this will be updated to actual adjustment value.

In the Comments field, enter any additional details related to the transaction.

lick  to save the physical inventory record. The Adjustment will populate

when the transaction is saved. An estimate for the adjustment will

be calculated. This value will be modified when the physical inventory

is valued during the global post process.

to save the physical inventory record. The Adjustment will populate

when the transaction is saved. An estimate for the adjustment will

be calculated. This value will be modified when the physical inventory

is valued during the global post process.